When it comes to driving a car, safety is key. One important component of vehicle safety is maintaining proper tire pressure. But how do you know if your tires are losing pressure? That’s where tire sensors come in.

These sensors can detect changes in tire pressure and alert you when it’s time to inflate your tires. However, installing a tire sensor can seem like a daunting task, especially if you’re not familiar with the process. In this blog post, we’ll walk you through the steps on how to install a tire sensor so you can have peace of mind knowing that your tires are properly inflated and you’re driving safely.

Table of Contents

What You Need

Installing a tire sensor is a crucial step in keeping your car safe and secure. It’s necessary to have the right tools before you start the installation process. You’ll need a tire pressure monitoring system tool, which enables you to mount the sensors on the wheels.

To start with, remove the valve cap and screw the sensor into the valve stem. Once the sensor is in, replace the valve cap and repeat the process for all the tires. Next, use the monitoring tool to enable the sensors to communicate with the car’s computer.

Make sure each sensor is functioning correctly and is transmitting data to the car’s monitor. Finally, test the sensor by using a tire gauge to check the air pressure. If all is well, you’re good to go, and you’ll have peace of mind knowing that your tires are being monitored for any issues constantly.

Installing a tire sensor does not take up too much time. So, spare some minutes, and you’ll skirt disasters potentially.

Tire Sensor

If you’re thinking about purchasing a tire sensor, there are a few things you should consider before making a decision. First and foremost, you need to think about the type of vehicle you have, as different sensors are designed for different kinds of cars. You may also need to consider the size of your wheels, as some sensors only work on specific wheel sizes.

Another thing to think about is how the sensor functions. Some sensors are designed to monitor air pressure, while others may also provide information about the tire’s temperature or even its specific location on the vehicle. These additional features may be useful if you’re tracking multiple sets of tires for different vehicles or if you need more detailed information about your car’s performance.

When choosing a tire sensor, you should also consider the quality of the product and the level of technical support provided by the manufacturer. Look for reviews from other customers and make sure the sensor you choose is reliable and accurate. And don’t forget to factor in the cost – while a high-end tire sensor may offer more features, it may not be necessary for your specific needs.

Overall, a tire sensor can be a valuable investment for anyone who wants to keep tabs on their car’s performance and safety. But before you make a purchase, be sure to do your research and choose a sensor that matches your vehicle and your needs. With the right sensor, you’ll be able to drive with greater confidence and enjoy a safer, more comfortable ride.

Valve Stem Tool

If you own a vehicle, you probably know the importance of checking the condition of your tires regularly. One crucial element in tire maintenance is the valve stem, which is responsible for maintaining adequate air pressure inside the tire. To ensure the valve stem is functioning correctly, you need a valve stem tool.

This tool comes in handy when changing tires or performing routine maintenance. Valve stem tools allow you to remove the valve stems from the rims effectively. It’s also an essential tool in preventing damage to the tire by avoiding over-inflation.

By having a valve stem tool at hand, you can save not only your time but also your money on costly tire replacements. It’s a must-have tool for all vehicle owners who value safety and want to maintain their tires in top-notch condition. So, next time you think about tire maintenance, don’t forget to check for the valve stems, and make sure you have a valve stem tool in your toolbox.

Tire Pressure Gauge

When it comes to maintaining a safe and efficient vehicle, one of the most important things you can do is regularly check your tire pressure. That means you’ll need a tire pressure gauge. But with so many different options on the market today, how do you know which one to choose? Well, it really depends on your specific needs.

Do you want a traditional analog gauge or a more modern digital one? Do you need a gauge that can also measure other things like tread depth or oil pressure? You’ll also want to consider the accuracy and durability of the gauge, as well as how easy it is to use. Whatever your needs may be, make sure to do your research and invest in a high-quality tire pressure gauge. It could be the difference between a smooth ride and a dangerous one.

Step 1: Remove the Old Valve Stem

If you’re looking to replace your tire sensor, the first step is to remove the old valve stem. This is a fairly simple process, but it does require a bit of care to make sure you don’t damage the tire. To start, you’ll need a valve core remover, which is a small tool that can be purchased at most auto parts stores.

Once you have the valve core remover, use it to take out the valve core from the stem. Next, use a valve stem puller to remove the old stem from the tire. Be sure to keep the tire steady and avoid pulling too hard, as this can damage the tire.

Once the old stem is out, you can clean the area around the valve hole with a bit of rubbing alcohol and a clean cloth. With that done, you’re ready to move on to installing the new tire sensor.

Deflate the Tire

Before installing a new valve stem on a tire, the old one must be removed. This can be done by using a valve stem remover tool to loosen and extract it from the valve stem hole. Once the old valve stem has been removed, the tire needs to be deflated completely by depressing the valve core with a valve stem tool or screwdriver.

It’s important to make sure that all air is released from the tire to enable the safe extraction and installation of the valve stem. Neglecting to deflate the tire completely could result in a dangerous blowout or injury, so it’s imperative to double-check that all air has been released. By taking the time to follow this critical step, you’ll be able to safely and effectively replace your tire valve stem.

Use the Valve Stem Tool

Valve Stem Tool If you want to change the valve stem on your tire, the first step would be to use a valve stem tool. This tool will help you remove the old valve stem from the tire without damaging it. The valve stem tool has two ends, one that fits around the valve stem and another that you use to pull the valve stem out of the tire.

First, you need to remove the cap on the valve stem, so you have access to it. Then, insert the end of the valve stem tool that fits around the stem and twist it anti-clockwise to loosen it. Once it’s loose, use the other end of the tool to pull out the valve stem gently.

Be careful not to damage the rim while removing the valve stem. In summary, using a valve stem tool is an essential step when changing a valve stem and ensures that you do it correctly without causing damage to your tire.

Step 2: Install the New Valve Stem with Sensor

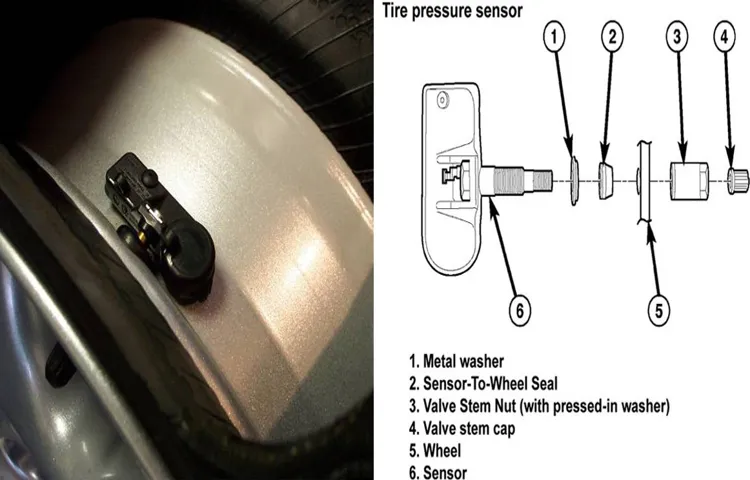

When it comes to installing a tire sensor, the second step is crucial. You need to install the new valve stem with the sensor correctly. Start by inserting the valve stem into the rim hole and tighten the nut using a wrench.

Once you’ve done that, put the sensor on top of the valve stem and thread the sensor onto the stem. Make sure the sensor is secured tightly. If you feel resistance during this step, that’s a good thing- it means the sensor is being properly installed.

When the sensor is securely in place, screw the valve cap onto the stem. This will protect the valve stem and sensor from external elements that may damage it. By following these steps, you’ll be well on your way to successfully installing a new tire sensor.

Insert the Sensor into the Valve Stem

To install a new valve stem with a sensor, the next step is to insert the sensor into the stem. Carefully remove the protective cap on the valve stem, then position the sensor so it lines up perfectly with the valve stem opening. Gently push the sensor into the valve stem until it clicks into place.

It should fit snugly and securely, but avoid using excessive force as this may damage the sensor or the valve stem. Once the sensor is seated firmly in the valve stem, replace the protective cap and double-check that everything is securely in place. This is an essential step to ensure your tire pressure monitoring system functions properly and keeps you safe on the road.

By taking the time to properly install the sensor, you will have peace of mind knowing your tires are working optimally and any potential issues will be detected and reported to you immediately.

Use the Valve Stem Tool to Secure

When it comes to installing a new valve stem with a sensor, it’s important to make sure you have the right tools for the job. One crucial tool is the valve stem tool, which will ensure that everything is securely in place. Begin by placing the new valve stem into the hole in the rim where the old one was removed.

Be sure to align it properly with the hole for the sensor. Then, use the valve stem tool to thread the nut onto the valve stem. Once you have the nut in place, use the valve stem tool to apply pressure and tighten it securely.

This will ensure that the valve stem stays firmly in place and the sensor can perform its job correctly. Don’t forget to double-check your work to ensure that everything is aligned and tightened properly before moving on to the next step. With the right tools and a little bit of care, you can install a new valve stem with a sensor without any trouble.

Inflate the Tire to Recommended Pressure

When installing a new valve stem with a sensor, it’s important to know how to properly inflate the tire to the recommended pressure. Once you have installed the new valve stem, it’s time to add air to the tire. The first step is to locate the recommended tire pressure.

This can typically be found in your car owner’s manual or on a sticker inside the driver’s side doorjamb. Use a tire pressure gauge to check the current tire pressure and compare it to the recommended pressure. If the pressure is too low, add air using a tire inflator.

If the pressure is too high, release some air until it reaches the correct pressure. It’s important to always inflate your tires to the recommended pressure to ensure proper handling, fuel efficiency, and to extend the life of your tires. By properly inflating your tires, you can help prevent accidents and keep your vehicle in top condition.

Step 3: Activate and Test the Sensor

Now that you have mounted the tire sensor and programmed it to your vehicle, the next step is to activate and test it. This is a crucial part of the installation process as you want to ensure that your sensor is functioning properly before hitting the road. To activate the sensor, start your vehicle and drive it for at least 10 minutes.

This will give the sensor enough time to connect to your vehicle’s computer system and begin transmitting data. Once you have driven for a sufficient amount of time, check your dashboard to see if the sensor is displaying the correct tire pressure readings. If everything looks good, take your vehicle for a spin to make sure the sensor is working properly at various speeds.

If you notice any abnormalities or inconsistencies, double-check your programming and positioning to make sure everything is correct. With a functioning tire sensor installed, you can breathe a sigh of relief knowing that you’ll be alerted to any changes in tire pressure before they become dangerous.

Refer to Sensor Manual for Activation Steps

As mentioned in the previous step, it is important to refer to the sensor manual for specific activation steps. Typically, activating the sensor involves pairing it with the corresponding device or hub, and ensuring that it is connected to a reliable network. Before testing the sensor, it is crucial to ensure that it has been activated properly.

Once activated, it is important to conduct thorough testing to ensure that the sensor is working as intended. This includes placing the sensor in the designated location and checking if it detects and reports any movement or changes in its environment. It may also be helpful to incorporate testing scenarios that emulate potential real-life situations, to ensure that the sensor can effectively detect and report any relevant activity.

By taking the time to properly activate and test the sensor, users can ensure that they get accurate and reliable data from their sensor, enhancing the effectiveness of their monitoring and automation systems.

Use the Tire Pressure Gauge to Ensure Accuracy

When it comes to activating and testing the sensor on your tire pressure monitoring system (TPMS), you want to be sure you’re doing it correctly. First, make sure your tires are properly inflated using a tire pressure gauge, as inaccurate tire pressure readings can lead to incorrect TPMS warnings. Next, start your car and let it run for a few minutes to allow the TPMS sensor to warm up.

Then, drive your car at a speed of at least 15 miles per hour for a few minutes to activate the sensor. Pay attention to the TPMS warning light, which should turn off once the sensor has been activated. If the light stays on, it could indicate a problem with your TPMS system that requires further inspection.

By following these steps, you can ensure that your TPMS sensor is working correctly and providing accurate readings to keep you safe on the road.

Conclusion

Now that you know how to install a tire sensor, you’ll never have to worry about driving around on low pressure ever again! Remember, tire sensors may be tiny, but they pack a powerful punch in ensuring your safety and the longevity of your tires. Plus, impress your friends with your newfound mechanic skills and show off that perfectly calibrated tire pressure gauge. Just don’t inflate your ego too much – keep your tires at the recommended pressure levels instead.

“

FAQs

What is a tire sensor?

A tire sensor is a small device that is installed inside a tire to monitor tire pressure and temperature.

Why is it important to have a tire sensor installed?

It is important to have a tire sensor installed because it alerts the driver if there is a change in tire pressure or temperature, which can prevent accidents and save on fuel costs.

Is it necessary to install a tire sensor for every tire?

Yes, it is necessary to install a tire sensor for every tire as each tire may have different pressure and temperature variations.

Can I install a tire sensor myself?

Yes, you can install a tire sensor yourself but it is recommended to go to a professional for installation to ensure proper installation and functionality.

How do I choose the right tire sensor for my vehicle?

You can choose the right tire sensor by checking the compatibility with your vehicle’s make and model, tire size, and recommended pressure range.

Do tire sensors need to be calibrated after installation?

Yes, tire sensors need to be calibrated after installation to ensure accurate readings.

Can the tire sensors be reused if I change my tires?

Yes, tire sensors can usually be reused if they are not damaged during the tire change process. However, it is recommended to check with a professional before reusing them.