As a car owner, you may have had to replace your tires at some point. While you could go to a professional for the task, you may also want to try using a tire machine yourself. The thought may seem daunting, but it doesn’t have to be.

With step-by-step instructions and a bit of practice, you can master the use of this tool in no time. First, make sure that the tire machine is securely placed on a level surface with enough space around it to accommodate the tire. Then, remove the valve core from the tire’s valve stem and deflate the tire completely.

Use the tire machine’s bead breaker to loosen the bead on both sides of the tire. Once this is done, use the tire machine’s mounting arm to lift the tire onto the machine. Use the tire lever to pull the tire bead over the rim’s edge, and ensure that the tire is centered.

Now, it’s time to inflate the tire. Use a bead sealer to lubricate the tire beads before inflating. Be sure to use the recommended air pressure for the tire’s size and type, and check for any leaks.

Finally, use the tire machine’s tire balancer to balance the tire properly. Though the process may seem complex at first, it becomes second nature with practice. With a little patience and attention to detail, you can become proficient in using a tire machine in no time.

Table of Contents

Safety Measures

Learning how to use a tire machine step by step is crucial for ensuring your safety while changing your car’s tires. Before operating the machine, put on proper safety gear, including eye protection and work gloves. Start by lining up the tire with the machine’s mounting head and secure it using the clamps.

Next, use the tire lever to pull the tire bead over the wheel rim. After mounting the tire, use the tire balancer to ensure your tire is evenly weighted. It is important to ensure that the machine is always in good working condition and is routinely serviced and maintained.

Always follow the manufacturer’s instructions and use caution when handling heavy equipment. Taking the necessary safety measures will prevent accidents and injuries when using a tire machine.

Check Machine’s Operating Manual

When working with machines, it’s essential to prioritize safety. One of the first things you should do is check the operating manual that comes with the machine. The manual should outline specific safety measures that need to be taken when operating the machine to prevent any accidents or injuries from occurring.

Make sure you carefully read and follow the instructions laid out in the manual, and don’t overlook any of the safety tips provided. Always keep in mind that these guidelines are written for your safety, and you must adhere to them as much as possible. Failure to abide by the instructions could lead to dangerous incidents, both for yourself and those around you.

Taking a few extra minutes to go through the manual could make all the difference in keeping you safe while working with machines. So, remember to check the machine’s operating manual and follow the safety measures to prevent mishaps that could cause harm.

Wear Protective Gear

When it comes to engaging in any physical activity, safety should always be the top priority. One of the crucial safety measures is wearing protective gear. Whether you’re going for a bike ride, playing contact sports, or doing home repairs, wearing the appropriate protective gear can drastically minimize your chances of getting injured.

Protective gear includes helmets, gloves, knee and elbow pads, goggles, and safety shoes, to name a few. Helmets are the most important protective gear, as they protect the head from impact injuries in case of falls or accidents. Similarly, knee and elbow pads protect the joints from being bruised or fractured during falls, while goggles protect your eyes from harmful debris or chemicals.

It’s essential to wear the correct gear for the activity you’re engaging in, and ensure that it fits properly. Wearing inappropriate or ill-fitting gear may do more harm than good and put you at a higher risk of injury. So, next time you engage in a physical activity, remember to put safety first and wear the necessary protective gear to keep yourself protected and injury-free.

Inspect the Tire and Rim for Any Damage

When it comes to taking care of your tires and rims, ensuring that they are in good condition is essential. This not only helps to extend their lifespan but also promotes safety while on the road. Before hitting the road, it’s crucial to inspect your tires and rims for any damages.

Look for cuts, punctures, bulges, or other damages that may affect the performance of your tires. If you notice any issues, replace or repair them as soon as possible. It’s also crucial to ensure that the rims are in good condition, as damaged rims can cause tires to wear unevenly or even come loose while driving.

Regularly inspecting your tires and rims can help you detect any issues early and take action before they become more severe. Remember, don’t compromise on safety – always ensure that your tires and rims are in top condition before hitting the road.

Prepping the Tire Machine

If you’re new to using a tire machine, the first step is to prep the machine for use. Begin by checking the tire machine for any damage or wear on the parts, such as the bead breaker and bead roller, before turning on the machine. After inspecting the machine, loosen and adjust the machine’s locking mechanisms according to the size of the tire you plan to use.

The next step is to lubricate the tire with soapy water to make it easier to mount on the rim. Once you have done this, place the tire on the tire machine and align it with the roller. Tighten the clamps around the rim to hold it in place and use the lever to control the height of the toolhead.

Finally, turn on the machine and begin the process of removing the tire from the rim. By following these simple steps, you’ll be able to use a tire machine step by step and avoid any complications.

Clean the Tire Mounting Surface

When prepping your tire machine, it’s important to make sure the tire mounting surface is clean. Any debris or dirt left on the surface can cause issues with the tire’s performance. Start by inspecting the surface for any cracks or imperfections that could damage the tire.

Once you’ve ensured the surface is in good condition, use a scraper or wire brush to remove any excess rubber or debris. Be sure to also check the bead seating area for any rust or corrosion, as this can prevent the tire from sealing properly. By taking the time to properly clean the tire mounting surface, you can help ensure a smooth and safe tire installation process.

Check the Machine’s Air Pressure

Before using a tire machine, it’s important to ensure that the air pressure is properly set. This can prevent accidents or damage to tires and rims. Checking the machine’s air pressure is a pretty simple process.

Locate the air pressure gauge, and if necessary, add air until the pressure meets the manufacturer’s recommendations. But don’t overinflate your machine; excessive pressure can cause your machine to malfunction or even explode, if left unchecked. If your machine is too low on air pressure, it may not have enough power to clamp down on the tire, making it difficult to properly mount or dismount.

Therefore, it’s crucial to check the air pressure beforehand, so you can work effectively and avoid accidents or mistakes in the process. Properly prepping your tire machine is necessary for both your safety and for achieving professional, accurate results.

Mounting the Tire on the Machine

If you’re wondering how to use a tire machine step by step, the next crucial step after mounting the tire is mounting it onto the machine. This involves attaching the tire to the rotary table and then locking it in place using the clamps or bead breaker. It’s essential to ensure that the tire is accurately centered on the table and that the bead is securely seated against the rim.

Once this is done, you can begin the process of inflating the tire using the air hose, being careful not to overinflate and cause damage. Additionally, it’s crucial to keep your hand on the tire as it begins to inflate to feel for any irregularities or issues. Overall, mounting the tire onto the machine is a critical step in the process, and it’s essential to follow all instructions carefully to avoid damaging the tire or the equipment.

Position the Wheel on the Mounting Surface

Mounting the tire on the machine can be a tricky task, but it’s an essential step in ensuring optimal performance. One of the critical steps is positioning the wheel on the mounting surface correctly. It’s crucial to ensure that the hub-centering ring is in the center of the wheel and fits snugly on the machine’s hub.

One helpful tip is to lubricate the hub with a thin layer of anti-seize, making mounting easier and protecting the rim from corrosion. After positioning the wheel, slide the lug nuts or bolts through the corresponding holes, ensuring they’re hand-tightened. Then, torque the nuts or bolts to the manufacturer’s specifications in a star pattern to evenly distribute the weight and prevent vibration.

With the tire securely mounted, you’re ready to hit the road confidently.

Secure the Wheel in Place with Jaws

When mounting a tire onto a machine, it’s essential to secure the wheel in place with jaws. The jaws serve as clamps that hold the wheel tight, ensuring it doesn’t move during the installation process. You don’t want the wheel to wobble or come loose when using the machine, as it could cause serious damage or injury.

The jaws are typically adjustable, allowing you to accommodate various wheel sizes and shapes. To use the jaws, you’ll need to position them around the wheel and tighten them until they’re snug. It’s crucial to ensure the jaws are properly aligned, so the wheel is balanced and stable.

Securing the wheel with jaws is a vital step in the tire mounting process, and it’s important not to overlook it. So, the next time you mount a tire onto a machine, remember to rely on the jaws to keep the wheel securely in place.

Lubricate the Tire Bead Area

When it comes to mounting a tire on the machine, lubricating the bead area is crucial. This ensures that the tire bead slides easily onto the rim without causing any damage. Applying a lubricant, such as soap or tire mounting paste, to the bead area reduces friction and helps the tire bead seat properly.

It’s important to note that using the right amount of lubricant is crucial for the tire to properly seat on the rim. Applying too little lubricant will not reduce friction, while using too much lubricant can cause the tire to slip and make it difficult to align properly. Remember, a well-lubricated tire bead area makes mounting the tire on the machine a quick and seamless process.

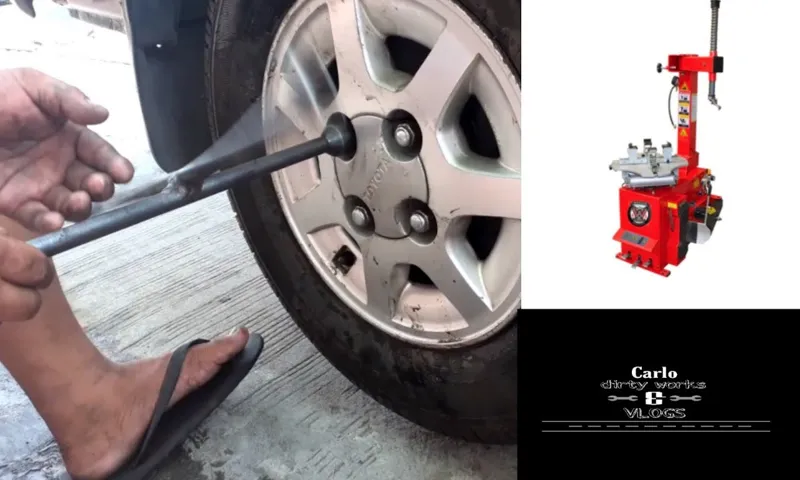

Insert the Tire Levers in the Bead Area

Mounting the tire on a machine can seem like a daunting task, but with the right tools and technique, it can be done smoothly. One essential tool that you’ll need is a tire lever. To begin, insert the tire levers into the bead area, which is the part of the tire that rests on the rim and holds it in place.

Gently pry the tire away from the rim, using the leverage of the lever to create enough space for the next lever. Insert the second lever slightly away from the first, and continue working your way around the tire. Be sure to use a steady and consistent motion to avoid damaging the tire or rim.

Once you have enough space, slide the lever around the rim, lifting the tire onto the machine. Remember to take your time, as rushing the process could lead to costly mistakes. With the tire securely mounted on the machine, you can now proceed with changing it.

So, why not give it a try and see how easy it can be with the right tools and technique!

Demounting the Tire

Learning how to use a tire machine step by step can seem daunting at first, but by breaking the process down into smaller sections, like demounting the tire, it becomes more manageable. To demount a tire, first, loosen the lug nuts and lift the vehicle using a car jack. Remove the lug nuts and the tire from the car, and deflate the tire completely.

Next, secure the wheel onto the tire machine using the clamps, making sure not to damage the rim. Once the wheel is secure, use the machine’s arm to loosen the tire from the rim, working your way around the tire until it is completely removed. Taking your time and paying attention to the details will help ensure that the tire is demounted safely and efficiently.

Remember, a tire machine can be a powerful tool, so it is always better to err on the side of caution. By following these steps, you’ll be well on your way to mastering the art of demounting a tire using a tire machine!

Deflate the Tire

Demounting a tire can be a daunting task, but it’s a necessary one when you need to replace or repair it. A crucial step in demounting a tire is deflating it. This allows you to loosen the bead of the tire from the rim easily.

To deflate the tire, first, you need to remove the valve cap from the tire’s valve stem. Next, press down on the valve stem’s center with a valve core removal tool or a small tool with a pointed tip. Hold it down until you hear the air escaping from the tire.

Once the tire is sufficiently deflated, use a tire iron to break the bead seal by wedging it between the tire and the wheel. This will allow you to remove the tire from the rim. Be sure to wear protective eyewear and gloves when performing this task to prevent injury.

Properly deflating the tire will make the rest of the demounting process much easier and efficient.

Push the Tire Down and Apply Pressure from Levers

Demounting a tire can seem like a challenging task, but knowing the right techniques can make the process a lot smoother. To begin, push the tire down and apply pressure from levers to loosen it from the rim. This action requires a bit of strength, so don’t be afraid to use some force.

Once you’ve managed to loosen the tire, use the levers to work your way around the rim, ensuring that you’re pulling the tire away from the rim as you go. It’s important to be patient and take your time with this step to avoid damaging either the tire or the rim. Overall, demounting a tire can be a bit tricky, but with the right technique and a bit of practice, you’ll be able to remove the tire with ease.

Remove the Tire from the Wheel

When it comes time to replace tires on your vehicle, demounting the old ones is a necessary step. To do this, you’ll need to remove the tire from the wheel. It’s important to take your time during this process and use the proper tools to ensure that you don’t damage the wheel or tire.

Start by loosening the lug nuts, but don’t remove them completely just yet. Use a jack to lift the vehicle off the ground and then finish removing the lug nuts. Once the wheel is off, you can begin the demounting process.

Use a tire iron to pry the tire away from the wheel bead, working your way around the circumference of the tire. When you’ve loosened it enough, you should be able to pull it off the wheel by hand. Be careful not to damage the valve stem or the rim of the wheel when you’re doing this.

Demounting a tire can be a bit of a tricky process, but with a little patience and the right tools, you can get the job done.

Finishing Up

Congratulations! You have successfully finished using the tire machine! Now it’s time to put your newly mounted tires on your vehicle and hit the road. But before you do, take some time to inspect your work. Ensure that the lug nuts are tightened to the manufacturer’s specifications, and check the tire pressure to make sure it’s within the recommended range.

It’s also a good idea to give your car a test drive to ensure that everything is working correctly. By following these step-by-step instructions on how to use a tire machine, you have safely and effectively mounted new tires on your vehicle, saving time and money in the process. Remember, always prioritize safety first, and if you encounter any difficulties or have concerns, seek the help of a professional.

Clean the Tire and Machine After Use

Finishing up your ATV adventure is just as important as starting it. One thing that is often overlooked is cleaning the tires and machine after use. This may seem like a minor task, but it can save you a lot of trouble in the long run.

Dirt, mud, and other debris can become lodged in the tires and machine, leading to decreased performance and potential damage. To clean the tires, start by spraying them down with a high-pressure hose. Use a brush to scrub away any dirt and debris, paying close attention to the treads.

For the machine, use a hose and bucket of soapy water to gently wash away any dirt or mud. Be sure to avoid getting water in any electrical components. Once everything is clean, let the machine and tires dry before storing it away.

Taking a few minutes to clean after use will keep your ATV running smoothly and prevent any unnecessary damage or repairs in the future.

Store the Tire Machine Properly

As you finish up using your tire machine, it’s important to give some thought to where and how you store it. You want to make sure it’s protected from the elements and not taking up too much space. First, give the machine a quick clean up to remove any excess dirt and debris.

Then, find a dry, covered area to store it in, away from direct sunlight or extreme temperatures. If you have limited space, consider investing in a cover or carrying case to keep it protected and out of the way. Taking good care of your tire machine will ensure that it lasts for years to come and is always ready for your next tire change.

Conclusion

Congratulations, you now possess the knowledge and skills to tackle the mighty tire machine! You’ve learned to carefully remove and replace tires, pump them up to the right pressure, and balance them for a smooth ride. With a little bit of patience and practice, you’ll soon be a tire-changing pro. So next time you need to swap out your tires, don’t hesitate to roll up your sleeves and get to work! And remember, whether you’re a speed demon or a weekend cruiser, the proper care and maintenance of your tires is essential for a safe and enjoyable driving experience.

So take care of your wheels, and they’ll take care of you! “

FAQs

What equipment is needed to use a tire machine?

To use a tire machine, you will need a tire changer, an air compressor, and a set of tire mounting tools.

How do I prepare the tire for mounting?

First, clean the rim and inspect it for any damage or defects. Then, apply lubricant to the rim and tire beads.

How do I remove the old tire from the rim?

Start by deflating the tire and removing any air pressure. Then, use the tire machine to break the bead and remove the tire from the rim.

How do I mount a new tire onto the rim?

First, place the tire onto the rim and align the markings. Then, use the tire machine to inflate the tire and seat the beads onto the rim.

What safety precautions should I take when using a tire machine?

Always wear safety glasses and gloves when using a tire machine. Make sure to follow the manufacturer’s instructions and only use the machine for its intended purpose.

Can I use a tire machine on all types of tires?

No, tire machines are designed for specific types and sizes of tires. Make sure to check the manufacturer’s instructions and specifications before using the machine.

How do I maintain my tire machine?

Regularly clean and lubricate the tire machine, and inspect it for any damage or wear. Follow the manufacturer’s recommended maintenance schedule for optimal performance.