“Have you ever found yourself stuck with a tire that just won’t come off its rim? It can be quite frustrating, especially when you’re in a hurry and need to get going. Breaking down a tire off the rim is not only a time-consuming task, but it can also be dangerous if not done correctly. This process involves removing the tire from the rim, which can be quite challenging since they are designed to fit snugly together.

Luckily, there are several techniques that you can use to make the process easier and safer. So, if you’re facing this problem, read on to find out how to break down a tire off the rim like a pro.”With that said, the process of taking a tire off a rim can be a daunting task if you don’t know how to do it correctly.

But don’t worry, in this blog post, we will be discussing the different methods and tools needed to help you break down a tire off the rim efficiently and quickly. From using a tire lever and lubricant to using a bead breaker, we’ve got you covered. Keep reading to learn more about breaking down a tire off the rim and make this task a breeze.

“

Introduction

If you’re looking to break down a tire off the rim, there are a few steps you can follow to make the process smoother. Firstly, loosen the lug nuts on the tire before jacking up the vehicle. Once the tire is off the ground, use a tire iron or pry bar to push the tire from the rim’s edge.

Work your way around the tire, using the tool to break down the seal between the tire and rim. It can take some effort, but keep pushing until the tire pops off the rim. With the tire off, inspect both the tire and rim for damage or wear, and replace or repair as necessary.

Breaking down a tire off the rim may seem daunting, but with the right tools and technique, it can be a straightforward process.

Why it’s Important to Know How to Break Down a Tire Off the Rim

Breaking down a tire off the rim is a skill that all vehicle owners and mechanics should possess. It involves taking the tire off the wheel to repair damages or replace it entirely. Knowing how to perform this task can come in handy in case of emergency situations.

But why is it essential to know how to break down a tire off the rim? Well, for starters, it saves you money and time. You don’t have to always go to a mechanic or repair shop to perform this minor task, which can be accomplished in a matter of minutes. Moreover, it gives you a better understanding of the mechanics behind the vehicles and their tires.

You learn how to operate the tools and equipment required to carry out this task and can even share this knowledge with friends and family. By mastering the technique of breaking down a tire off the rim, you become better equipped to handle vehicular problems and make more informed decisions when it comes to tire replacement. It’s essential to acquire this skill to save time, money, and gain a better understanding of the intricacies of your vehicle’s wheels.

Tools You’ll Need

When it comes to breaking down a tire off the rim, you’ll need a few tools to make the process easier. Firstly, you’ll need a tire iron, which can be used to pry the tire away from the rim by inserting it into one of the gaps between the tire and the rim. Additionally, you’ll need a valve stem removal tool to take out the valve stem before you deflate the tire.

This tool is crucial as it prevents any air from getting in or out of the tire while you’re working on it. An air compressor or a tire pressure gauge is also necessary to ensure that the tire is fully deflated. Lastly, you’ll need gloves and goggles to protect your hands and eyes from any debris that may fly off during the process.

With these tools in hand, breaking down a tire off the rim can be a straightforward and easy process, even if it may be a bit messy.

Tire Iron

When it comes to fixing a flat tire on your own, having the right tools is essential. One of the most important tools you’ll need is a tire iron. A tire iron, also known as a lug wrench, is used to loosen the lug nuts that hold your wheel in place.

These nuts are usually tightened to a high torque and can be difficult to loosen without the right tool. Tire irons come in various sizes, so it’s important to check your car’s manual to see what size you need. If you don’t have a tire iron, you’ll likely need to call for roadside assistance or find a nearby mechanic to assist you.

Investing in a quality tire iron can save you time and money in the long run, so it’s definitely worth having in your car’s emergency toolkit. So, next time you’re planning a road trip or just going on a quick drive, make sure you have a tire iron handy just in case.

Lubricant

If you’re planning on lubricating your tools, there are a few things you’ll need before you get started. First and foremost, you’ll need the right lubricant for the job. There are several types of lubricants available, such as grease or oil, so make sure to choose the one that’s suitable for your specific needs.

You’ll also need a clean and dry workspace, as well as a set of gloves to protect your hands from any potential spills or splashes. Additionally, you may want to consider using a small brush or applicator to help distribute the lubricant evenly across your tools. The last thing you’ll need is some patience and a bit of time, as lubricating your tools can be a time-consuming process, but it’s well worth the effort in the long run.

By taking the time to properly lubricate your tools, you’ll help ensure their longevity and keep them functioning at their best.

Work Gloves

When it comes to working with your hands, whether on DIY projects at home or managing a professional trade, having the right tools is essential. In particular, work gloves play a vital role in ensuring your safety and comfort while getting the job done. There are a few key types of work gloves that you should consider investing in, depending on your needs.

For example, leather gloves are great for heavy-duty work and can protect your hands from cuts and abrasions, while rubber gloves are perfect for working with chemicals or in wet conditions. Additionally, there are specialized gloves designed for welding, gardening, and other specific tasks. Regardless of the type of gloves you choose, it’s important to select a pair that fits well and provides adequate protection.

With the right tools at your disposal, you can work safely and effectively, tackling any project with confidence and ease.

Steps to Follow

If you need to take apart a tire from the rim, don’t worry – it’s not as daunting as it may seem! Follow these simple steps and you’ll have the tire broken down in no time. First, release all the air pressure in the tire by removing the valve core with a valve core tool. Then, unseat the tire bead from the rim using a tire iron or pry bar, starting at the valve stem and working your way around the tire.

Next, use a tire lubricant to help separate the tire from the rim. Insert your tire iron or pry bar between the tire and rim and work it around the wheel until you are able to fully separate the tire from the rim. Repeat this process on the opposite side of the tire before removing it completely.

Breaking down a tire off of the rim may take a bit of elbow grease, but with these easy-to-follow steps, you’ll be able to handle it like a pro!

Step 1: Loosen the lug nuts

When it comes to changing a tire, it may seem like a daunting task, but with the right steps, anyone can do it. The first step in changing a tire is to loosen the lug nuts. To do this, you will need to use a lug wrench.

Place the wrench onto the lug nut and turn it counterclockwise. Be sure to only loosen the lug nuts at this stage, as you will need to fully remove them later. Loosening the lug nuts can be difficult, especially if they have been tightened too much or if there is rust on them.

If this is the case, apply some lubricant to the lug nuts and wait a few minutes before attempting to loosen them again. Remember to always turn the wrench towards the operator, as this uses the strongest muscles in the arm and will make it easier to loosen the lug nuts. By following these steps, you’ll be well on your way to successfully changing your tire.

Step 2: Lift the Car

When it comes to lifting your car, there are a few steps you should always follow. Step 2 is to lift the car itself. This can be done with a jack, which is typically included in most car emergency kits.

Start by finding a sturdy and level surface to work on. Then, locate the jack points on your car, as specified in the owner’s manual. Place the jack under one of these points and start cranking it up.

It’s important to take your time and make sure the car is steady before moving on to any repairs or maintenance. Remember to always use caution when working with a jack, and never place any part of your body under a car that is being lifted. Following these simple steps can help ensure your safety and the safety of your car while performing basic maintenance or repairs.

Step 3: Remove the lug nuts and tire

When it comes to changing a tire on your vehicle, it’s important to follow all the necessary steps to ensure your safety and the proper function of your vehicle. Step 3 involves removing the lug nuts and tire, which requires both physical strength and careful attention to detail. After you’ve properly jacked up your vehicle and secured it with jack stands, use a lug wrench to loosen the lug nuts on the wheel you need to remove.

Be sure to turn them counterclockwise, and don’t remove them entirely just yet. Once the lug nuts are loose, use a tire iron or your hands to remove them completely, taking care to keep them in a safe place where you won’t lose them. After the lug nuts have been removed, you can then carefully pull the tire off the wheel hub and set it aside.

Remember, each step in the tire changing process is important, so take your time and don’t rush through anything. By following these steps, you’ll be well on your way to successfully changing a tire.

Step 4: Lubricate the tire and rim

When it comes to maintaining your bike tire, one crucial step that you shouldn’t overlook is lubrication. The tire and rim require proper lubrication to prevent rust, corrosion, and ensure that they function correctly. To lubricate the tire and rim, you’ll need to apply a thin layer of oil or grease on the surface using a clean cloth or brush.

Ensure that you apply the lubricant on the rims’ spoke nipples, as this is where the metal parts come into contact. Besides, it’s essential to lubricate the axle nuts, bearings, and all moving parts to ensure that they move with ease. Lubricating your tire and rim is a simple process that’ll go a long way in maintaining your bike’s performance.

So, make sure to add it to your bike maintenance routine to avoid unnecessary frustrations down the line.

Step 5: Use a tire iron to break the bead

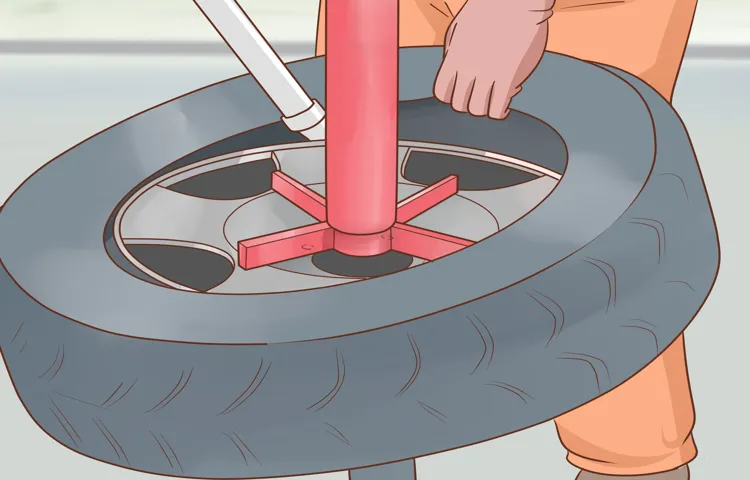

Breaking the bead on a tire can seem like a daunting task, but with the right tools and technique, it’s actually quite simple. Once you’ve removed the valve core and deflated the tire, it’s time to use a tire iron to break the bead. This step requires a bit of strength, as you’ll need to lever the tire iron between the tire and rim to create enough force to break the seal.

It’s important to work slowly and carefully, placing the tire iron at several points around the rim to ensure that the bead is fully broken. This might take some patience, but be persistent and the bead will eventually give way. With the bead broken, you can now move on to removing the tire from the rim.

Overall, breaking the bead is an essential step in the tire repair process, and with the right technique, you’ll be able to do it with ease.

Step 6: Push down on tire and lift the rim up

When it comes to changing a tire, there are specific steps you need to follow to ensure a smooth and successful process. One crucial step is to push down on the tire while lifting the rim up. This might seem counterintuitive, but it’s essential to make sure the tire is properly seated onto the rim before tightening the lug nuts.

By pushing down on the tire, you’re helping to create a seal between the tire bead and the rim flange. This ensures a secure fit and helps prevent any air from escaping. Once the tire is seated, you can begin tightening the lug nuts, making sure to do so in a star pattern to evenly distribute the tension.

By following these steps, you can change your tire with confidence, knowing your tire is correctly seated and secure. So, the next time you find yourself with a flat tire, don’t panic, simply follow these steps and you’ll be back on the road in no time.

Step 7: Remove the tire from the rim

When it comes to removing a tire from a rim, there are a few important steps to follow to ensure a safe and successful process. The seventh step is to actually remove the tire from the rim itself. This step requires a bit of strength and patience, as the tire can be quite snug around the rim.

First, locate the valve stem and deflate the tire fully. Next, use a tire iron or pry bar to wedge between the tire and rim, near the outside edge of the tire. Work your way around the tire, placing the iron in different spots and gently prying the tire away from the rim.

As you move around the tire, take care not to damage the rim or the tire itself. Once the tire has been fully separated from the rim, you can lift the tire off of the rim and set it aside. With the tire removed, you can now proceed with any necessary repairs or replacement before re-installing the tire onto the rim.

By following these steps carefully, you can remove a tire from a rim safely and effectively.

Conclusion

Breaking down a tire off the rim may seem like a daunting task, but with the right tools and techniques, it can be a breeze. Just like anything in life, you must first have a plan of attack and assemble the necessary tools to get the job done. With patience and persistence, you’ll be able to conquer even the toughest tire and rim combinations.

And who knows, perhaps you’ll even develop a newfound appreciation for the art of tire disassembly. So go forth, my fellow tire enthusiasts, and break down those rims like the champions you are!”

Tips to Keep in Mind

When it comes to buying a new car, it’s important to take your time and do some research beforehand to make sure you’re making the right decision. Here are some steps to follow:Determine your budget – Before you start browsing for cars, it’s essential to know how much money you’re comfortable spending.

This will help you narrow down your options and avoid overspending.Consider your needs – Think about your lifestyle and what kind of car would suit it.

Do you need a large SUV for a family, or a small and fuel-efficient car for commuting?Research models – Once you know your budget and needs, start researching different makes and models of cars that fit your criteria. Check out consumer reports, online reviews, and ask friends and family for recommendations.

Take a test drive – Don’t buy a car without taking it for a test drive first. This will give you an idea of how the car handles and feels on the road.

Negotiate the price – Don’t be afraid to negotiate the price with the dealership. Do your research beforehand and come prepared with information on the car’s value and comparable prices in your area.

By following these steps, you can make a well-informed decision and find a car that meets your needs and budget. Remember, buying a car is a big investment, so take your time and do your due diligence.

Practice Makes Perfect

“Practice Makes Perfect: Steps to Follow for Achieving Mastery”Have you ever heard the saying “Practice makes perfect”? It’s true! In order to master a skill, you have to practice it consistently. But simply practicing isn’t enough – you need to follow some specific steps to truly achieve mastery.First, set specific goals.

What do you want to achieve through practicing this skill? Break your goals down into achievable, measurable steps. This will help you stay motivated and focused.Next, ensure that you’re practicing correctly.

Seek out resources such as tutorials, articles, and videos to help guide your practice. Be sure to get feedback from others, too – whether it’s a teacher, mentor, or peer.Consistency is key.

Set aside some dedicated time each day or week to practice your skill. Even if it’s just a few minutes, make sure you’re making a regular effort to improve.Finally, don’t forget to enjoy the process.

Practicing a skill is hard work, but it can also be enjoyable. Celebrate your milestones along the way and remember to have fun with it.Remember: Practicing a skill is the key to achieving mastery.

By setting specific goals, practicing correctly, staying consistent, and enjoying the process, you’ll be on your way to becoming a pro in no time!

FAQs

What tools do I need to break down a tire off the rim?

You will need a tire iron, a bead breaker, and a rubber mallet to break down a tire off the rim.

Can I break down a tire off the rim without a bead breaker?

It is possible to break down a tire off the rim without a bead breaker, but it can be difficult and time-consuming.

How can I protect the rim when breaking down a tire?

You can use a rim protector or a piece of cardboard to protect the rim when breaking down a tire off the rim.

What is the safest way to break down a tire off the rim?

The safest way to break down a tire off the rim is to use proper tools and follow the manufacturer’s instructions carefully.

Do I need to remove the valve stem to break down a tire off the rim?

You do not need to remove the valve stem to break down a tire off the rim, but it can make the process easier.

How do I know if the tire is fully broken down off the rim?

You will know the tire is fully broken down off the rim when the bead is completely separated from the rim.

Can I reuse the tire after breaking it down off the rim?

Yes, you can reuse the tire after breaking it down off the rim, but you will need to clean and inspect it for any damage or wear.