Tire valve stem issues can be a pain – and more often than not, they happen when you least expect it. But don’t fret because fixing a tire valve stem is easier than you think. It’s something anyone can do with the right tools and a little bit of knowledge.

In this step-by-step guide, we’ll walk you through the process of fixing a tire valve stem like a pro. You’ll learn what causes a faulty valve stem, how to identify the problem, and what tools you need to get the job done right. Whether you’re a seasoned mechanic or a beginner, this guide is perfect for anyone looking to save money and time on fixing their tire valve stem.

Get ready to roll with confidence, no matter where the road takes you!

Introduction

If you’ve noticed that your tire is losing air or suspects there’s a problem with the valve stem, don’t fret because fixing it is relatively easy. If you’re experiencing this issue, the first step is identifying the problematic valve stem. With the help of a soapy water solution, check for bubbles around the valve stem, which would indicate a leak.

To fix the valve stem, remove the valve cap and take out the valve core using a valve core tool. Then replace it with a new one. However, if it’s not the valve core that’s causing the issue, try tightening the valve stem’s retaining nut with a valve stem tool.

And if that doesn’t solve the problem, you may need to replace the entire valve stem. In summary, how to fix a tire valve stem is pretty simple. Just identify the problem, replace the valve core if needed, tighten the retaining nut, and if all fails, replace the valve stem altogether.

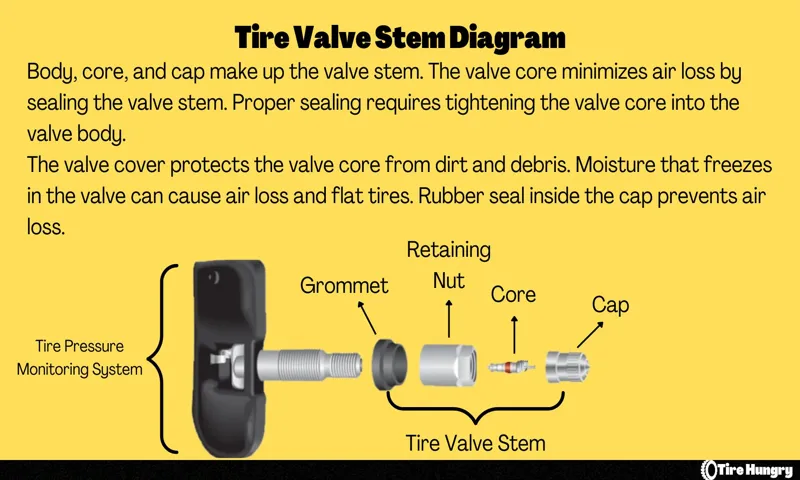

Understanding Valve Stems and their Function

Valve stems are an essential component of proper wheel functioning. These small components connect the tire to the inner wheel and allow for proper inflation and deflation. Without a functioning valve stem, tires cannot hold the correct amounts of air, which can lead to decreased performance, lower fuel efficiency, and even safety issues.

Understanding how valve stems operate is critical to maintaining a smooth ride. So, whether you’re inspecting your vehicle for wear and tear, or simply want to understand the workings of your wheels, learning about valve stems is an essential first step.

Assessing the Damage

If you notice your tire losing air more rapidly than usual, there’s a high chance the valve stem is to blame. The valve stem is responsible for maintaining proper air pressure within the tire, and damage to the valve stem can lead to air leakage. To fix a tire valve stem, you’ll first need to assess the damage.

If the valve stem is simply loose or not sealing properly, tightening it or replacing the valve core might solve the issue. However, if the valve stem is bent, damaged, or broken, it will need to be replaced entirely. In such cases, it’s best to take your tire to a professional mechanic.

They will have the expertise to diagnose and fix the problem, ensuring your tire is safe and road-ready.

Signs Your Valve Stem Needs Repair or Replacement

Valve Stem Repair or ReplacementHave you noticed a problem with your car’s handling lately? Are the tires losing air pressure faster than usual? It might be time to assess the condition of your valve stems. These small but important components play a crucial role in maintaining proper tire pressure and ensuring smooth driving. So, how do you know if your valve stems need repair or replacement? Some signs to look out for include visible cracks or damage on the stems, difficulty in inflating or deflating the tires, and consistent air leaks.

In some cases, valve stems may become loose or corroded over time, leading to more serious issues like tire blowouts or accidents. If you suspect any damage to your valve stems, it’s important to have them checked by a professional mechanic right away. Don’t wait until it’s too late!

Equipment and Tools Required

When assessing the damage after a plumbing disaster, you’ll want to have the necessary equipment and tools on hand. At a minimum, you’ll need safety gear such as gloves, goggles, and a mask to protect yourself from hazardous materials. You’ll also need basic tools like a wrench and pliers to turn off water valves and disconnect pipes.

If you suspect leaks or cracks in your pipes, you may want to invest in tools like a pipe cutter, soldering iron, or a torch to make necessary repairs. It’s essential to have a flashlight or headlamp to inspect hard-to-reach areas, and a moisture meter to detect hidden damage. Taking stock of what equipment and tools you have on hand before disaster strikes can save you time and stress in the long run.

Repairing the Tire Valve Stem

If you’ve ever experienced a flat tire due to a damaged valve stem, you know how frustrating it can be. But don’t worry, fixing a tire valve stem is a straightforward process that you can do yourself. First, you’ll need to remove the faulty valve stem by unscrewing it with pliers.

Then, use a valve stem tool to insert the new valve stem into the hole. Make sure it’s tight enough to seal the hole properly. Finally, use a tire pressure gauge to check the pressure and inflate the tire to the proper pressure level.

That’s it! With these easy steps, you can quickly and easily repair a tire valve stem and get back on the road in no time. So, the next time you encounter this problem, don’t panic. Instead, take a deep breath and fix it yourself!

Step 1: Removing the Valve Core

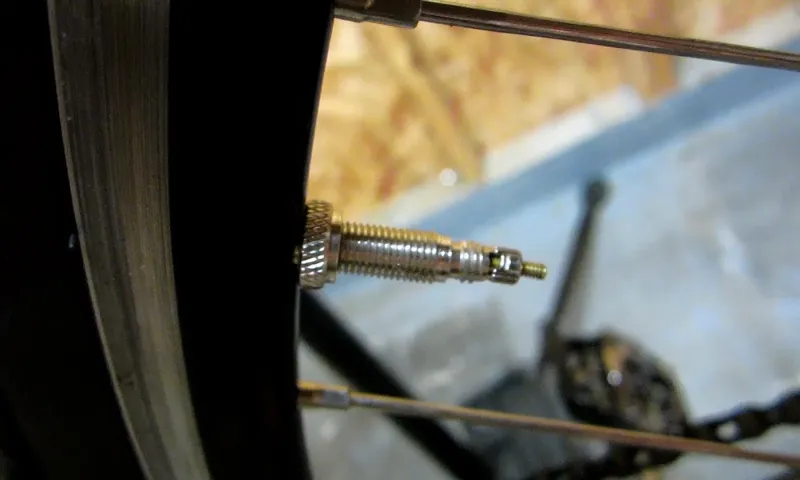

When it comes to repairing the tire valve stem, the first step is to remove the valve core. This can be done easily using a valve core remover tool. The tool should be placed over the valve stem, and then turned counterclockwise to remove the core.

Once the core is removed, it’s important to inspect it for any damages or debris that may have caused the issue in the first place. If the core is damaged, it will need to be replaced before moving forward with any further repairs. It’s also important to clean the valve stem to remove any dirt or debris that may have accumulated around the area.

This will ensure that the new valve core is inserted properly and will prevent any leaks in the future. Removing the valve core is a crucial first step in repairing a tire valve stem and shouldn’t be skipped. By following this process, the tire valve stem can be properly repaired to ensure safe and reliable operation.

Step 2: Removing the Damaged Valve Stem

When it comes to repairing a tire valve stem, the second step is removing the damaged valve stem. This may sound intimidating, but with a few tools and basic knowledge, it’s a task that can be easily accomplished. Start by deflating the tire completely and removing the valve core with a valve core removal tool.

Then, use a valve stem tool to remove the entire valve stem from the wheel. It’s important to take note of how the old valve stem was positioned on the wheel and replicate that position when installing the new one. This step is crucial to ensure the proper fit and function of the new valve stem.

With the old valve stem removed, you can now move onto the next step of repairing your tire. Remember, taking the time to do the job right will save you time and money in the long run and keep you safe on the road.

Step 3: Installing the New Valve Stem

Repairing the tire valve stem requires a few steps, including installing the new valve stem. This is a crucial step in ensuring your tire doesn’t lose air and remains safe to drive on. The first step is to remove the old valve stem and discard it.

Next, take your new valve stem and insert it into the hole in the rim. Make sure it fits snugly and is seated properly. Then, use a valve stem tool to tighten the valve stem nut, ensuring it is secure and won’t leak air.

Finally, inflate the tire to the recommended pressure and check for leaks around the valve stem. Installing a new valve stem may seem like a small task, but it can make a big difference in the overall safety and reliability of your vehicle. Keeping your tire valves in good working order can help prevent unexpected flats and keep you on the road without any hassle.

Step 4: Replacing the Valve Core

When it comes to repairing a tire valve stem, replacing the valve core is a crucial step. The valve core regulates the air pressure within the tire, and if it is damaged or not functioning correctly, the tire won’t hold the air pressure necessary for safe driving. To begin, you’ll need a valve core removal tool, which can be found at most auto parts stores.

Then, you’ll need to remove the old valve core from the valve stem by unscrewing it with the removal tool. Make sure to keep track of the old valve core as it will need to be replaced with a new one. Once the old valve core is removed, insert the new valve core into the valve stem and tighten it with the removal tool.

It’s important to make sure the new valve core is threaded correctly and tightened to avoid any leaks. By replacing the valve core, you can ensure the tire will hold the proper air pressure, allowing for safer driving on the road.

Replacing the Valve Stem

If you’re experiencing a leaky tire or constantly having to refill air, it’s possible that the valve stem may be damaged or worn out. Don’t worry, fixing the valve stem is actually quite simple. First, remove the valve cap and use a valve core remover tool to release any air pressure in the tire.

Next, unscrew the valve stem using pliers or a valve stem removal tool. Be sure to keep track of any washers or o-rings. Once the old valve stem is removed, insert the new valve stem and make sure it’s securely in place.

Then, replace any washers or o-rings and tighten the valve stem back into place. Finally, inflate the tire and check for any leaks. By replacing the valve stem, you can save yourself the hassle of constantly refilling your tire and potentially causing further damage.

Step 1: Removing the Entire Valve Stem Assembly

Replacing the valve stem can seem like a daunting task, but it’s actually relatively simple. The first step is to remove the entire valve stem assembly. To do this, you’ll need a valve stem removal tool, which is a specialized tool designed for this job.

Start by removing the valve stem cap, which is the small cap on the tip of the valve stem. Next, insert the valve stem removal tool into the valve stem and turn it counterclockwise. Keep turning the tool until the entire valve stem assembly comes out.

It’s important to remember to be gentle when removing the valve stem assembly, as it can be fragile and break if you apply too much force. By following these steps and being cautious, you can successfully remove the valve stem assembly and move on to the next step of replacing the valve stem.

Step 2: Installing the New Valve Stem Assembly

Replacing the valve stem assembly is a task that requires a bit of know-how, but with some careful consideration, it can be done in no time. Once you have removed the old valve stem, it’s time to install the new assembly. First, take your new valve stem and place it through the hole in the rim.

Then, place the valve nut onto the valve stem and hand-tighten it until it is snug against the rim. Make sure not to over-tighten, as this could cause damage to the stem. Next, use a valve stem tool to tighten the valve nut until it is securely in place.

Once the valve stem assembly is tightly secured, you can inflate the tire to the recommended pressure. Now you’re ready to hit the road confidently with your newly-installed valve stem. Remember to check your tire pressure regularly to ensure a safe and smooth ride.

Conclusion

In conclusion, fixing a tire valve stem is as easy as ABC. With just a few simple steps, you can be back on the road in no time. Don’t let a flat tire deflate your spirits – take charge and get it fixed! Just remember, when it comes to valve stems, don’t be a dummy, use your common sense and get your tires pumped up right!”

FAQs

What causes a tire valve stem to fail?

Tire valve stems can fail due to wear and tear, damage from external factors such as road debris, or improper installation.

Can a tire valve stem be repaired or must it be replaced?

In most cases, a tire valve stem must be replaced rather than repaired. Attempting to repair a valve stem can be dangerous and may not provide a long-lasting solution.

How can you tell if your tire valve stem needs to be replaced?

Signs that your tire valve stem may need to be replaced include a noticeable leak in your tire, difficulty inflating your tire, or if the valve stem is visibly damaged or worn.

Is it safe to drive on a tire with a faulty valve stem?

It is not safe to drive on a tire with a faulty valve stem as it can cause sudden deflation and increase the risk of a tire blowout.

How often should tire valve stems be inspected?

Tire valve stems should be inspected every time you have your tires rotated, and at least once a year. Regular inspections can help identify any potential issues early on and prevent tire failures.

Can you replace a tire valve stem yourself or should it be done by a professional?

While it is possible to replace a tire valve stem yourself, it is recommended that it be done by a professional tire technician. This ensures that the valve stem is installed correctly and the tire is properly inflated.

Are all tire valve stems the same size and type?

No, tire valve stems come in different sizes and types depending on the type of tire and vehicle. It is important to use the correct valve stem for your specific tire and vehicle to ensure proper inflation and safety.