If you’re new to the world of bearings, you might be surprised to learn that they require regular maintenance to ensure they keep functioning smoothly. One of the most critical parts of bearing maintenance is lubrication. When it comes to sealed bearings, it may seem challenging to know how to grease them without damaging the seal.

But don’t worry, in this blog, we’ll take you through all the steps on how to grease a sealed bearing effectively, quickly, and without any mess. So keep reading to learn how to keep your bearings functioning at their best.

Introduction

If you’re wondering how to grease a sealed bearing, don’t worry, it’s not as complicated as it may seem. Greasing a sealed bearing means you’re making sure it has a sufficient amount of lubrication to run smoothly without any issues. The first step is to remove the seal on the bearing using a needle or a thin screwdriver.

Once the seal is off, clean the bearing with a solvent or degreaser. Then, using a grease gun, apply a small amount of grease into the bearing. It’s important not to over-grease the bearing as this could lead to overheating and damage.

After that, replace the seal and spin the bearing to distribute the grease evenly. That’s all there is to it! Regular maintenance of sealed bearings will ensure their longevity and smooth operation.

Understanding Sealed Bearings

sealed bearingsSealed bearings are an essential component of many machines, including cars, bicycles, and industrial equipment. These types of bearings are designed to protect the internal components from debris, moisture, and other contaminants that can cause damage. By keeping the internal components clean and lubricated, sealed bearings can significantly extend the lifespan of the machine.

One of the critical benefits of sealed bearings is that they do not require maintenance, as they are designed to last for a long time without needing replacement. This means that they are particularly useful in machines that are difficult to access or that operate in harsh environments, where regular maintenance is not practical. Overall, sealed bearings are a crucial part of many different machines and play a significant role in keeping them running smoothly and reliably.

Why Greasing Is Important

Greasing is a term that refers to the application of lubricants to mechanical components of machinery in order to reduce friction between the surfaces in contact. Although it may seem like a minor aspect of maintenance, greasing is actually very important for the proper functioning and longevity of machines. Without proper lubrication, the metal parts of machines can grind against each other, leading to wear and tear and eventual breakdowns.

This is why it is crucial to apply grease regularly to moving parts in order to keep them working smoothly. In fact, proper greasing can prevent a multitude of issues and save a lot of money in the long run by avoiding expensive repairs or replacements.

Tool Requirements

If you’re wondering how to grease a sealed bearing, you’ll need a few tools to get started. First and foremost, you’ll need a good quality grease. Look for a high-quality, high-temperature grease that is specifically formulated for use with bearings.

You’ll also need a grease gun to apply the grease. Make sure the grease gun is compatible with the type of grease you have chosen, and that it has a small nozzle that will fit into the bearing. You may also need a bearing packer, which is a tool that helps to evenly distribute the grease inside the bearing.

If you don’t have a bearing packer, you can use a clean toothbrush or your fingers to pack the grease in as evenly as possible. Finally, you’ll need some rags or paper towels to clean up any excess grease that may be left over after you’ve finished greasing the bearing. By having the right tools on hand, you can ensure that your sealed bearings are properly lubricated and working smoothly.

What You Will Need

When it comes to tackling DIY projects, having the right tools can make all the difference in the world. Before you begin any project, it’s essential to ensure you have all the necessary tools to get the job done right. Some basic tool requirements you should have on hand include a hammer, screwdrivers, pliers, tape measure, level, and saw.

Depending on the project, you may also need power tools like a drill, jigsaw, circular saw, or sander. These power tools can help save time and effort while achieving accurate results. Additionally, it’s crucial to have appropriate safety gear like gloves, goggles, and ear protection.

Having the right tools not only makes the project easier, but it also ensures that the results are professional and long-lasting. So, before you start your next project, take the time to evaluate what tools you have and what you may need to invest in to get the job done right the first time.

Preparing the Bearings

When preparing your bearings, you’ll need a few essential tools to ensure the job is done right. The first tool you’ll need is a bearing puller. This tool is designed to remove the bearing from its housing safely.

The second tool is a bearing packer, which helps to ensure the bearings are lubricated correctly. You’ll also need a bearing installer to help you reinstall the bearings back into place. Other tools you may need include a torque wrench, seal driver, and a set of snap ring pliers.

Keep in mind that the specific tools you’ll need may vary depending on the type of bearing you’re working with. Overall, using the correct tools is crucial to preparing your bearings properly and ensuring they work efficiently for years to come.

Greasing the Sealed Bearing

Do you have a sealed bearing that needs to be greased? Don’t worry, it’s actually a simple process. Just follow these steps. First, remove the bearing from the machine or equipment it’s in.

Then, using a clean cloth or paper towel, wipe away any dirt or grime on the outside of the bearing. Next, take your grease gun and load it with the recommended type of grease for your bearing. Slowly apply the grease into the small gap between the inner and outer rings of the bearing, making sure not to over-grease it.

Once the bearing is fully greased, wipe away any excess grease and replace it back into its original location. It’s important to remember that over-greasing a sealed bearing can cause it to malfunction, so be sure to use the proper amount of grease. With a little bit of effort, you can ensure that your sealed bearing will continue to function smoothly and efficiently.

Step-by-Step Greasing Process

Greasing the sealed bearing can be a simple process if you follow the steps accordingly. Before starting, you need to have the correct lubricant and the right grease gun to apply it. The first step is to clean the bearing and the surrounding areas.

Use a degreaser or a cleaning solution to remove any debris, dirt, or old grease that may have accumulated. Once you have cleaned the bearing, ensure it is dry before proceeding. Next, apply grease to the bearing’s lip or edge, making sure to cover the entire surface.

Be cautious not to over-grease as it may lead to overheating or cause damage to the seal. Finally, use a clean rag to wipe off any excess grease on the surface of the bearing, and you’re done! Regular maintenance is essential to ensure the bearing’s longevity. By following these easy steps, you can increase the efficiency of the sealed bearing and reduce any potential problems.

Using the Right Grease

When it comes to greasing sealed bearings, using the right type of grease is crucial. Sealed bearings are designed to be low-maintenance, but that doesn’t mean they don’t need to be lubricated from time to time. Using the wrong type of grease can cause damage to the bearing and reduce its lifespan.

It’s recommended to use a high-quality, waterproof grease that is formulated specifically for sealed bearings. This type of grease will protect the bearing from moisture, dirt, and other contaminants that can cause wear and tear. Applying the grease correctly is also important.

It’s best to apply a small amount of grease evenly around the bearing, being careful not to over-grease. Regular maintenance is key to ensuring the longevity of your sealed bearings. Don’t forget to clean and inspect them periodically, and always use the right type of grease for the job.

Removing Excess Grease

When it comes to maintaining your bike, a crucial aspect is greasing the sealed bearing. However, it’s important to ensure there isn’t excess grease on the bearing, as it can attract dirt and other grime, causing damage in the long run. To avoid this, first, remove any excess grease on the bearing using a clean microfiber cloth or cotton swab.

Then, use a light hand to apply a small amount of grease to the bearing’s surface, ensuring you cover the entire area. Remember, too much grease isn’t as effective as a thin layer applied evenly. The goal is to provide enough grease to protect the bearing without having excess that can attract debris.

By following these simple steps, you’ll ensure that your sealed bearing is properly greased and maintained for a smooth ride.

Conclusion

Greasing a sealed bearing is like giving your car a tune-up – it’s a necessary maintenance task that ensures everything runs smoothly. Just like how your car needs an oil change, sealed bearings need a little grease to keep them spinning and moving like a well-oiled machine. So if you want your wheels to keep on turning and your ride to stay smooth, don’t hesitate to grease those bearings!”

When to Grease Sealed Bearings

Sealed bearings are often said to be maintenance-free, which can leave many people wondering when to grease them. The truth is, while sealed bearings are designed to keep dirt and debris out, they still require regular maintenance to function properly. In fact, neglecting to lubricate sealed bearings can lead to premature wearing and eventual failure of the bearing.

That’s why it is crucial to follow the manufacturer’s recommendation for greasing intervals. Generally, sealed bearings should be re-lubricated every 12 to 18 months or after a certain number of hours of operation. However, it is always a good idea to check the manufacturer’s recommendation to ensure you don’t miss any critical maintenance intervals.

To maintain the optimal performance of sealed bearings, it is important to use high-quality, compatible grease and apply it in the right amount. By following these guidelines, you can maximize the lifespan of your bearings and avoid costly repairs or replacements.

Safety Precautions to Take

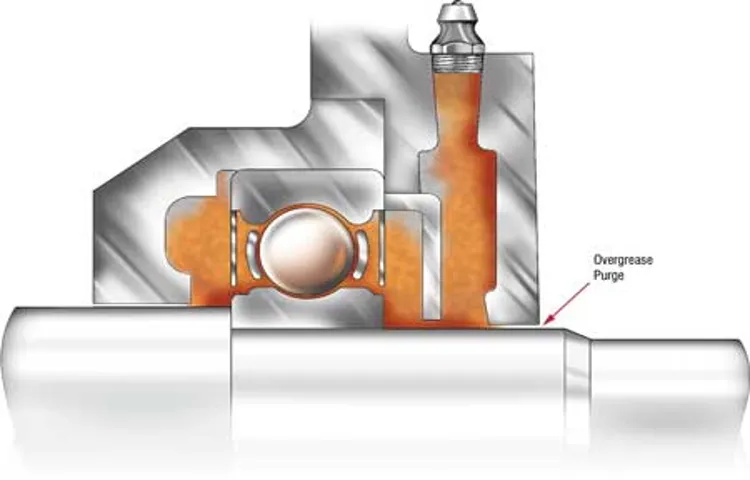

As a responsible equipment owner, greasing your sealed bearing is one safety precaution that you should never overlook. Bearings play an essential role in keeping your machine running smoothly, and greasing them regularly prolongs their lifespan and ensures maximum efficiency. The process of greasing a sealed bearing is quite simple.

First, use a grease gun to pump the grease towards the bearing until it overflows. Then, wipe off any excess grease with a rag, and you’re good to go. Overgreasing your bearing can cause it to run hot, leading to premature failure.

Undergreasing it, on the other hand, means that the bearing may not be able to endure the heavy loads it’s designed to carry. Therefore, it’s crucial to find the right balance and follow your manufacturer’s recommendations for greasing intervals. By keeping your bearings well-lubricated, you’re not only ensuring their longevity but also reducing the risk of unexpected breakdowns which can be costly in the long run.

Final Thoughts

Sealed bearings are an essential part of many machines and pieces of equipment. These bearings prevent dirt and other contaminants from entering the bearing and causing damage to the equipment. However, over time, sealed bearings can become dry and lose their lubrication, which can cause friction and ultimately lead to failure of the bearing.

To prevent this from happening, it’s important to grease the sealed bearing regularly. Greasing a sealed bearing involves injecting grease into the bearing through a small hole or port. By doing so, it ensures that the bearing stays lubricated and performs its intended function effectively.

Remember, greasing a sealed bearing frequency depends on the equipment, and it’s crucial to adhere to the manufacturer’s guidelines. Failure to do so may result in permanent damage to the machine.

FAQs

What is a sealed bearing?

A sealed bearing is a type of ball or roller bearing that is pre-lubricated and enclosed with a seal to prevent dirt, dust, and debris from entering the bearing.

Why should I grease a sealed bearing?

While sealed bearings are pre-lubricated, adding extra grease can help prolong their lifespan and improve their performance by reducing friction and heat build-up.

Can I use any type of grease on sealed bearings?

No, it’s important to use a grease that is specifically designed for sealed bearings, such as a high-temperature synthetic grease. Using the wrong type of grease can cause damage to the bearing and compromise its sealing properties.

How often should I grease my sealed bearings?

It depends on the application and usage, but generally, greasing once a year or every 10,000 miles (for automotive bearings) is recommended. However, it’s always a good idea to check the manufacturer’s recommendations for your specific bearing.

What tools do I need to grease a sealed bearing?

You will need a grease gun, the appropriate grease for your bearing, and a bearing packer or your hands to apply the grease directly to the bearing.

Should I remove the seal before greasing a sealed bearing?

No, you should not remove the seal as it can compromise the bearing’s ability to keep out debris and contaminants.

Can over-greasing a sealed bearing cause damage?

Yes, over-greasing can cause excessive pressure to build up inside the bearing and damage the seals. It’s important to only apply the recommended amount of grease.