If you’re new to the world of trailering, one of the most important things you need to learn is how to grease your trailer bearings properly. Neglecting to do this can lead to costly repairs and even accidents on the road. But, where do you start? Don’t worry, we’ve got you covered with this beginner’s guide to greasing trailer bearings.

First things first, let’s break down what trailer bearings are. These are the small metal balls that allow your wheels to spin freely. They’re packed inside a race, which is basically a metal ring that holds the bearings in place.

These bearings need grease to keep them lubricated and prevent friction, heat buildup, and ultimately, wear and tear.Now, when it comes to greasing your trailer bearings, the first step is to inspect them for any damage or wear. This can include signs of abrasion or cracking on the outer race, pitting or discoloration on the bearings, or excessive wear on the spindle.

If you notice any of these issues, it’s best to replace them before greasing.Assuming your trailer bearings are in good shape, the next step is to remove the wheels and hubs to access the bearings. Typically, you’ll need a wrench and a jack to do this.

Once you have access to the bearings, clean them thoroughly with a solvent or cleaning solution. This will remove any old grease or debris that could cause further damage.Finally, it’s time to grease the bearings! You’ll need a high-quality grease designed for use in trailer bearings.

Apply the grease evenly, making sure to cover all the bearings and races. Don’t overfill, as this can cause the grease to spit out and create a mess.In conclusion, greasing your trailer bearings is an essential part of trailer maintenance.

What are Trailer Bearings?

If you’re new to owning a trailer, you may be wondering what trailer bearings are and why they need to be greased. Trailer bearings are small metal balls or rollers that help your trailer’s wheels rotate smoothly on their axles. Like any mechanical part, they can wear out or become damaged over time, which can cause your trailer to wobble or even come off its wheels.

To prevent this from happening, it’s important to regularly grease your trailer bearings. To do this, you’ll need to remove the bearing from the wheel hub, clean it thoroughly with a solvent, and then pack it with fresh grease before returning it to the hub. This will not only keep your trailer running smoothly, but it will also prolong the life of your bearings and save you money in the long run.

So don’t neglect your trailer’s bearings – give them the TLC they deserve!

Description of Trailer Bearings

Trailer bearings are an essential component of a trailer’s wheel system. They enable smooth rotation of the wheels, reducing friction and wear. But what exactly are trailer bearings? Well, they are small metal balls or rollers that sit inside a ring-shaped casing.

These bearings are responsible for supporting the weight of the trailer and allowing the wheels to spin freely. Without these bearings, the wheels would be prone to seizing up or overheating, which could cause significant damage to the trailer and its cargo. It’s essential to ensure that your trailer bearings are regularly inspected, maintained, and replaced when needed to keep your trailer rolling safely down the road.

So, if you notice any grinding, clicking, or rumbling noises coming from your trailer’s wheels, it might be an indication that your trailer bearings need attention. Don’t ignore these warning signs. Get them checked out by a professional to avoid any costly breakdowns on the road.

Why is Greasing Trailer Bearings Important?

Trailer bearings are an essential part of any trailer’s wheel system, and it is important to keep them properly lubricated to ensure safe and smooth operation. These bearings are essentially small metal balls that sit inside races or channels, allowing the wheels to spin freely. Over time, dirt, dust, and water can accumulate inside the bearings, causing them to wear down and eventually fail.

This can lead to serious damage to your trailer and even put you and others on the road in danger. By greasing your trailer bearings regularly, you can prevent this from happening, ensuring that your trailer runs smoothly and safely whenever you hit the road. So, don’t neglect the importance of keeping your trailer bearings greased!

Preparations Before Greasing

Before greasing the trailer bearing, there are several preparations that you should consider to ensure that the process runs smoothly. Firstly, you should ensure that you have all the necessary tools and equipment, such as a jack, lug wrench, and grease gun, in order to avoid any interruptions during the process. Additionally, you should check the manufacturer’s recommendations for the type of grease that is suitable for your trailer’s bearings and ensure that you have the correct type of grease on hand.

It’s also advisable to clean the area surrounding the bearing to prevent any dirt or debris from entering the bearing during the greasing process, as this could cause damage. Taking the time to prepare and gather everything you need beforehand will make the process of greasing your trailer bearing much more efficient and effective in the long run. So, get to work, and don’t forget to apply enough grease to keep your trailer running smoothly!

Tools and Materials

GreasingBefore starting any project involving greasing, it’s important to make sure you have all the necessary tools and materials at your disposal. These might include a grease gun, rags, a scraper or brush, and of course, the appropriate lubricant or grease. Once you have everything you need, it’s time to begin preparing the area you’ll be working on.

This might include cleaning the surface with a degreaser or other cleaning agent, removing any old grease or lubricant, and ensuring the area is free from dirt or debris. It’s also important to ensure you have a safe work environment, with appropriate lighting and ventilation. By taking the time to prepare properly, you can ensure that your lubrication job is both effective and safe.

Safety Precautions to Take

When it comes to greasing machinery and equipment, safety should always be a top priority. Before beginning the greasing process, it is essential to prepare properly to ensure no accidents occur. First and foremost, make sure the equipment is turned off and locked out to prevent any unexpected movements.

It is also vital to wear appropriate personal protective equipment such as gloves, goggles, and clothing that covers all exposed skin. Before beginning the greasing process, familiarize yourself with the machinery’s lubrication points and the type of grease required to avoid any mistakes. Taking these precautions can prevent unnecessary injuries and ensure the job is done correctly.

Remember, safety first, always!

How to Grease Trailer Bearings

If you’re not sure how to grease a trailer bearing, don’t worry – it’s not a difficult task once you know what you’re doing. The first step is to remove the dust cap from the hub of the wheel you’re working on. Then, use pliers or a flathead screwdriver to remove the cotter pin and loosen the nut holding the bearing in place.

Take care not to lose any of the small parts as you work. Next, you’ll need to clean out the old grease from the bearings and hub, using a clean rag or paper towel. Once everything is clean, apply a fresh coat of quality grease to the bearings and the hub, taking care not to overfill.

Finally, replace the nut, tightening it just enough to leave a slight amount of play in the wheel. Replace the cotter pin and dust cap, and you’re done! It’s a good idea to grease your trailer bearings at least once a year, or more often if you use your trailer frequently. By keeping your bearings well-lubricated, you’ll extend the life of your trailer and ensure smoother, safer towing.

Step-by-step Guide to Grease Trailer Bearings

If you own a trailer, you know the importance of keeping your bearings properly lubricated. Not only does it ensure a smooth ride, but it also prolongs the life of your trailer’s wheels. But how do you grease trailer bearings? It’s actually quite easy, and we’ll walk you through it step by step.

First, you’ll need to jack up the trailer and remove the wheels. Then, remove the dust cap and castle nut, and pull off the wheel hub. Clean the bearings with a solvent, and inspect them for any signs of wear or damage.

Apply fresh grease to the bearings, making sure to pack it in tightly. Reassemble the wheel hub, making sure to torque the castle nut to the manufacturer’s recommended specifications. Finally, replace the dust cap and wheel.

And that’s it! With regular maintenance, your trailer bearings will stay properly lubricated and last for years to come.

How Often to Grease Trailer Bearings

If you own a trailer, it’s important to maintain its bearings by greasing them regularly. This simple maintenance task will help ensure that your trailer operates smoothly and prevents any potential damage to the wheel bearings. So, how often should you grease your trailer bearings? Well, it depends on how often you use your trailer and the distance you travel.

A good rule of thumb is to grease the trailer bearings every 12 months or 12,000 miles, whichever comes first. However, if you frequently use your trailer for long distances and under extreme weather conditions, it’s best to grease them more frequently. Remember, failing to grease your trailer bearings can cause friction and ultimately lead to wheel bearing failure.

In the end, taking care of your trailer’s bearings by greasing them will avoid more costly repairs and provide peace of mind on the road.

Common Mistakes to Avoid

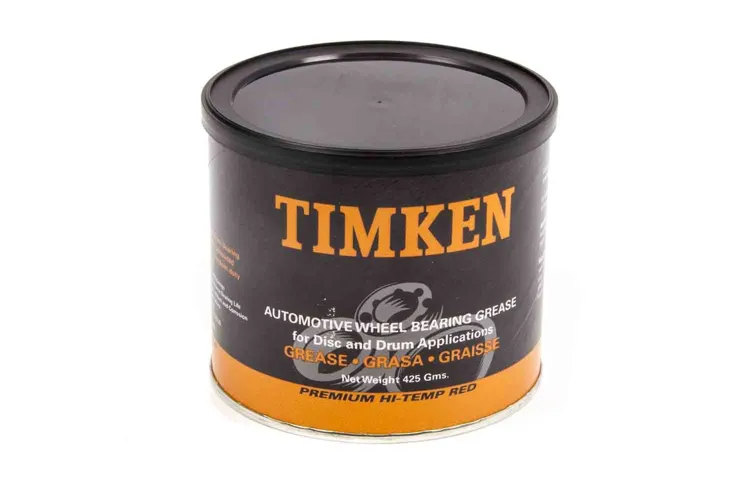

When it comes to maintaining your trailer, greasing the bearings is an important task to ensure your trailer is running smoothly. However, there are some common mistakes to avoid to ensure proper maintenance. Firstly, one mistake is not using the correct type of grease.

It’s important to use high-quality grease that is formulated specifically for your trailer’s bearings. Secondly, over-greasing can cause just as many issues as not greasing enough. Over-greasing can cause damage to the bearings and even push out seals.

Thirdly, not cleaning the bearings before greasing can lead to contamination and reduce the effectiveness of the grease. Lastly, not inspecting the bearings regularly can lead to unnoticed wear and tear, ultimately leading to more expensive repairs. By avoiding these common mistakes and following proper greasing procedures, you can keep your trailer’s bearings in top shape.

Over-greasing or Under-greasing

When it comes to greasing, there are two common mistakes that many people make – over-greasing and under-greasing. Over-greasing can lead to unnecessary waste of grease, as well as negatively affect the performance of the machine. This is because excess grease can create an additional layer of insulation on the bearing, leading to an increased temperature.

On the other hand, under-greasing can cause the machine to wear out faster, leading to expensive repairs and downtime. Therefore, it is crucial to find the right balance between over and under-greasing. It’s important to follow the manufacturer’s recommendations for greasing intervals and the amount of grease required.

By doing so, you can ensure that your machine has the proper amount of lubrication to function smoothly and efficiently. Remember, finding the right balance is key to maintaining your equipment’s lifespan and saving you money in the long run.

Wrong Type of Grease

When it comes to lubricating moving parts in machinery, using the wrong type of grease can cause some serious problems. It’s important to understand the characteristics of different types of grease and make informed decisions based on the needs of each application. One common mistake is using a general-purpose grease for specialized machinery, which can result in poor performance and premature wear.

Another mistake is mixing incompatible types of grease, which can cause the grease to break down and lose effectiveness. To avoid these issues, always consult the manufacturer’s recommendations and use the appropriate grease for each specific application. By taking the time to choose the right product, you can ensure the longevity of your machinery and prevent costly repairs down the line.

Remember: a little bit of research goes a long way!

Conclusion

Now that you know how to grease a trailer bearing, you’ll be the envy of all your friends. Just remember, a little lubrication goes a long way in keeping your trailer rolling smoothly. However, if you really want to impress them, try doing it in a top hat and monocle.

Classy AND practical, what more could you ask for?”

FAQs

What are the benefits of greasing a trailer bearing?

Greasing trailer bearings increases their longevity, helps reduce friction and heat, and ensures smoother functioning of the trailer.

How often should you grease trailer bearings?

Trailer bearings should be greased at least once a year, or after approximately 12,000 miles of use, whichever comes first. However, it is recommended to grease them more frequently if you use your trailer frequently or in harsh weather conditions.

How to prepare trailer bearings for greasing?

First, jack up the trailer and secure it with jack stands. Then, remove the wheels and dust covers of the bearings to expose the bearing races. Clean the bearings and races thoroughly with a suitable solvent and dry them completely.

What type of grease should be used for trailer bearings?

The grease used for trailer bearings should be a high-temperature, water-resistant, and heavy-duty wheel bearing grease. Check the manufacturer’s recommendations for the specific type of grease to be used.

Is it possible to over-grease trailer bearings?

Over-greasing trailer bearings can cause damage to the seals and lead to contamination of the grease. It is recommended to use a grease gun and apply a moderate amount of grease until it is visible at the front and back of the bearing.

Can trailer bearings be greased without removing the wheels?

While it is possible to grease trailer bearings without removing the wheels, it is not recommended as it may not allow proper inspection and cleaning of the bearings and races, which is crucial for their longevity and smooth functioning.

What are the signs of worn-out or damaged trailer bearings?

Signs of worn-out or damaged trailer bearings include unusual noises or vibrations, overheated wheels, or difficulty in rolling the trailer. It is recommended to inspect the bearings regularly for signs of wear and replace them as needed.