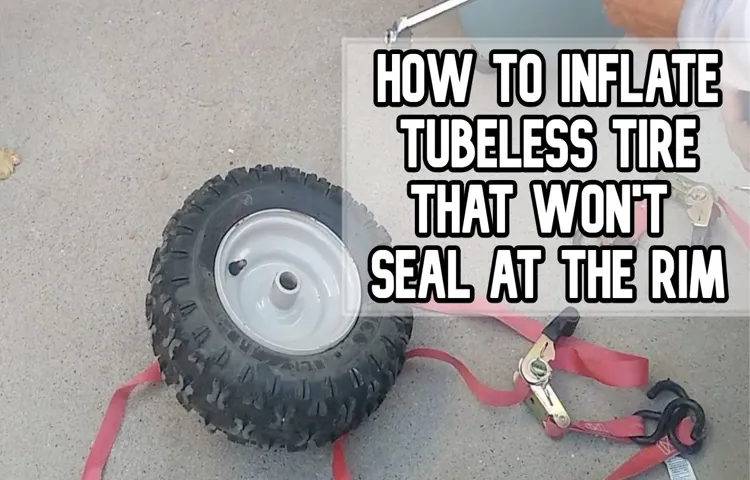

Have you ever found yourself with a flat tubeless tire that is not sealed on a rim? It can be quite frustrating, especially if you don’t know how to inflate it properly. Many people assume that inflating a tubeless tire without a rim is the same as inflating a regular tire, but there are actually a few key differences to keep in mind. In this blog post, we’ll take a closer look at how to properly inflate a tubeless tire without a rim and what you need to know to avoid any mishaps.

So, get ready to dive into the world of tubeless tire inflation!

Tools Required

If you find yourself with a tubeless tire that is not sealed on the rim, inflating it can be a frustrating experience. But fear not! With the right tools, this task can be accomplished easily and quickly. You will need an air compressor, a tubeless tire inflator, and a tire sealant.

The air compressor is essential to provide the high pressure needed to seat the tire onto the rim. A tubeless tire inflator will help you to accurately inflate the tire without the need to remove the valve core. Lastly, the tire sealant is used to add a layer of protection against punctures and to help seal the tire onto the rim.

By having all these tools ready, you’ll be back on the road in no time. Don’t forget to check your tire pressure regularly, especially after a puncture, to keep your tires running smoothly.

Example: Air Compressor, Tire Gauge, Tubeless Tire Repair Kit

When it comes to maintaining your tubeless tires, having the right tools on hand is crucial. One essential piece of equipment is an air compressor, which can help you inflate your tires to the correct pressure quickly and easily. A tire gauge is also essential, as it allows you to check your tire pressure regularly and make sure everything is running smoothly.

If you experience a puncture or other issue while on the road, a tubeless tire repair kit can be a real lifesaver. These kits typically include plugs and other materials that allow you to patch up small holes and get back on the road in no time. Of course, it’s important to choose high-quality tools that are designed specifically for use with tubeless tires.

With the right equipment on hand, you can enjoy a smoother, safer ride and avoid any potential tire-related issues down the line.

Step 1: Identify the Leak

Are you having trouble inflating your tubeless tire that is not sealed on the rim? The first step is to identify where the leak is coming from. Start by removing the tire from the rim and inspecting the inner surface. Look for any punctures or cuts in the rubber or any debris that may have caused the leak.

You can also feel around the rim to check for any burrs or rough edges that could have damaged the tire. If you can’t find any visible damage, try filling the tire with soapy water and looking for bubbles. The bubbles indicate the location of the leak, and you can then patch or replace the damaged area.

By identifying the leak and knowing where to focus your efforts, you can effectively inflate your tubeless tire and get back on the road in no time.

Example: Use Soapy Water to Locate the Specific Area of Damage

Identifying a leak in your plumbing, whether it’s in a wall or under the floor, can be a challenge. One effective method for locating the specific area of damage is to use soapy water. Begin by turning off any water sources and draining the pipes.

Then, mix dish soap or liquid detergent with water in a spray bottle. Spray the mixture around the suspected area, and watch for bubbles to form. If you see bubbles, you have found the leak.

This method works because the air escaping from the hole in your pipe reacts with the soap solution to create bubbles. It’s a simple but effective way to identify the location of most leaks quickly and without damaging anything further. Remember to stay vigilant with your pipes so that you can catch any leaks early and before they do significant damage.

Step 2: Remove the Tire from the Rim

After identifying that your tubeless tire is not sealed on the rim, the second step is to remove the tire from the rim. This can be achieved using a variety of tools, including tire levers or a tire bead jack. First, release all the air from the tire by removing the valve core.

Then wedge the tire lever between the tire and rim, prying the tire away from the rim. Continue this process all the way around the tire until the bead is loose on both sides. Using both hands, push down on one side of the tire to pop the bead over the edge of the rim and repeat on the other side.

Once the tire is removed, it is important to inspect the rim and tire for any damage or debris that may have caused the seal to break in the first place. With your tire off the rim, you are now ready to proceed with inflating the tire.

Example: Use Tire Levers or a Bead Breaker Tool

Removing a tire from a rim can be a challenging process, but it’s necessary to repair or replace a tire. One of the most effective tools for removing a tire from rim is tire levers. These handy tools work by prying the tire away from the rim, making it easier to unseat the tire bead from the wheel.

Start by placing one tire lever under the tire bead and push down to create a gap. Then, insert another lever next to the first and repeat the process, moving around the tire until it’s loose enough to remove by hand. It may also be helpful to use a bead breaker tool to break the seal between the tire bead and wheel, making it easier to remove.

Be sure to work slowly and carefully, being mindful not to damage the rim or tire during the process. With patience and the right tools, removing a tire from a rim can be a relatively simple task.

Step 3: Clean the Inner and Outer Surface of the Tire and Rim

If you’ve got a tubeless tire that’s not sealed on the rim, you’ll need to clean both the inner and outer surfaces before inflating it. This is important for creating a secure seal and preventing any air from escaping. Start by spraying both surfaces with a degreaser or rubbing alcohol and wiping it down with a clean cloth or paper towel.

Then, use a wire brush or sandpaper to rough up the rim where the tire sits. This will help create more friction between the tire and rim, improving the seal. After cleaning and roughing up the surfaces, inspect the tire and rim for any damage or debris that could interfere with the seal.

Once everything looks good, you can move on to inflating the tire. Remember to use the correct pressure for your tire and to keep an eye on it for the first few rides to ensure that it’s holding air properly.

Example: Use a Clean Rag or Brush to Remove Dirt, Dust, and Debris

When it comes to cleaning the inner and outer surfaces of your tires and rims, it’s important to start with a clean rag or brush to remove any dirt, dust, and debris. This will ensure that you don’t scratch or damage the surface of your wheels while cleaning them. Once you’ve removed any loose particles, you can move on to using a cleaning solution specifically designed for tires and rims.

Be sure to follow the instructions on the product label and apply it evenly to both the inner and outer surfaces of your wheels. Use a soft-bristled brush to gently scrub away any grime or buildup, paying special attention to any hard-to-reach areas. Rinse thoroughly with a hose or pressure washer, making sure to remove all traces of the cleaning solution.

Finally, give your tires and rims a good wipe down with a clean, dry rag to remove any remaining moisture and leave them looking shiny and new. By taking the time to properly clean your tires and rims, you’ll not only improve their appearance but also extend their lifespan and ensure optimal performance on the road.

Step 4: Insert Sealing Solution into the Tire

So you’ve managed to get your tubeless tire on the rim, but now what? If you find yourself struggling with a tubeless tire that won’t seal properly, don’t worry! The solution may be easier than you think. The next step is to insert the sealing solution into the tire to help seal the beads to the rim. This sealing solution typically comes in a bottle that’s similar in shape to a water bottle.

Fill the bottle with the solution and remove the valve core from the tire using a valve tool. Then, attach the bottle to the valve and squeeze the solution into the tire, ensuring that the entire bottle is emptied. Once the solution is in the tire, reinsert the valve core and inflate the tire to the recommended pressure.

The sealing solution should seal any small punctures or gaps between the tire and rim. Keep in mind that it may take a few minutes for the solution to work properly, so give it some time before hitting the road. By following this simple step, you’ll be able to inflate your tubeless tire and hit the road with confidence and ease.

Example: Use a Tubeless Tire Sealant or DIY Formula

Now that you have properly mounted your tubeless tire on the rim, it’s time to add the sealing solution. You can either use a commercially available tubeless tire sealant or make your own DIY formula. If you’re going for the latter option, you’ll need a few ingredients such as liquid latex, glitter (optional), and ammonia-based window cleaner.

Mix them all together, and you have yourself a sealing solution.Inserting the sealing solution into the tire is straightforward. First, remove the valve core using a valve core remover tool.

Then, using a sealant injector, pour the desired amount of sealing solution into the valve stem. Insert the valve core back in and inflate the tire to the recommended pressure specified by the manufacturer. Give the tire a good shake and spin to ensure an even distribution of the sealing solution.

The sealing solution works by sealing any punctures or cuts in the tire’s casing as they occur, thereby preventing air from escaping and keeping your tire inflated for longer. It also helps to create an airtight seal between the tire bead and rim, preventing air leaks through the bead. Depending on how much sealing solution you add, it can last anywhere from a few months to a year before needing to top it up.

In conclusion, using a sealing solution is a crucial step in ensuring your tubeless tires remain puncture-free and inflated for longer. Whether you decide to use a commercially available tubeless tire sealant or make your own DIY formula, be sure to follow the instructions carefully and add the recommended amount of solution. With proper installation and maintenance, your tubeless tire can provide you with a more comfortable and efficient riding experience.

Step 5: Re-install the Tire onto the Rim and Inflate with an Air Compressor

Inflating a tubeless tire that is not sealed on the rim can be a bit of a challenge, but it’s not impossible. Before you begin, you’ll need an air compressor, tire sealant, a tire lever, and a valve core remover tool. First, remove the valve core with the valve core remover tool to allow air to flow freely into the tire.

Next, position the tire onto the rim, making sure the bead is in place. Then, attach the air compressor to the valve stem and inflate the tire to the recommended pressure. Finally, listen for any leaks and apply tire sealant to any spots where air is escaping.

This should seal up the tire and prevent any further leaks. Once the leak has been sealed, re-check the tire pressure and adjust if necessary. With these steps, you’ll be able to inflate a tubeless tire that is not sealed on the rim and get back on the road in no time.

Example: Use a Tire Gauge to Check and Adjust the Air Pressure as Needed

After you have inspected your tire for damages and adjusted the air pressure to the recommended level, it’s time to re-install the tire onto the rim. Make sure that the tire is seated properly onto the rim and that the rim is centered between the beads of the tire. It’s important to note that not all tires are created equal, so it’s crucial to check your vehicle’s manual for the recommended inflation pressure.

Once you have the proper pressure, you can use an air compressor to inflate your tire. It’s important not to overinflate your tire, as this can cause it to wear out more quickly and increase your risk of a blowout. If you don’t have an air compressor, many gas stations provide air pumps for a small fee.

Always remember to recheck the tire pressure after inflating and adjust as necessary. By following these steps, you can ensure that your tire is in good condition and ready for the road ahead.

Step 6: Check the Sealing and Air Retention of the Tire

If you’ve properly installed a tubeless tire but it’s not sealing on the rim, there are a few steps you can take to remedy the situation. First, inflate the tire to the recommended pressure and then let it sit for a few minutes. If the tire loses pressure, it may be due to a faulty valve or a puncture in the tire.

Check the valve stem for leaks and use soapy water to identify any punctures. Once any leaks have been patched or the valve replaced, reinflate the tire and let it sit for a few minutes to ensure it retains air. If the problem persists, check the sealing tape or rim strip to make sure it’s properly aligned and covering the spoke holes.

Additionally, check the bead of the tire for any deformities or gaps in the seal. Using a tire lever, reseat the tire bead if necessary and reinflate to the recommended pressure. Before hitting the trails, give the tire a quick spin to ensure it’s running true and retaining air.

By following these steps, you can ensure a properly sealed tubeless tire for a smooth ride.

Example: Use Soapy Water to Test the Tire for Leaks

Now that you’ve checked the tire pressure, it’s time to check the sealing and air retention of the tire. One effective way to do this is by using soapy water. Simply mix a small amount of dish soap with water in a spray bottle and spray it onto the tire.

Then, observe if there are any bubbles forming. If there are, it means that air is escaping the tire and you have a leak. The soap works by creating a film over the tire surface, and the air escaping from the leak creates a bubble.

This method is quick and easy and allows you to identify any potential leaks before they cause a major issue. Remember to check all areas of the tire, including the valve stem, bead seating areas, and the tread surface. By doing so, you can ensure that your tire is properly sealing and retaining air for optimum performance on the road.

Conclusion

Inflating a tubeless tire that’s not sealed on the rim is like blowing up a balloon with a hole in it- it takes some extra effort and cleverness, but it’s not impossible! By following these steps, you can safely and effectively get your tubeless tire up and running, no matter how stubborn it may seem. So don’t let a loose seal deflate your enthusiasm- with a little bit of know-how, you can always stay one step ahead of the flat tire game!”

Example: Tubeless Tire Inflation Requires Patience, Care, and Safety Measures

Now that you have inflated your tubeless tire correctly, it’s time to check its sealing and air retention. The importance of this step should not be underestimated as it ensures safety and prevents any mishaps on the road. To check for sealing, gently tap around the rim and listen for any hissing sounds.

If any are present, verify that the tire’s sealing tape is correctly aligned and there are no punctures on the tire. Then, carefully inspect the tire and look for any visible leaks. If none are visible, slowly rotate the tire and check for small leaks.

It’s best to do this step indoors or in a confined area to ensure that any air leaks are easily noticeable. Once you have checked the sealing, it’s time to assess the air retention of the tire. Ideally, a tubeless tire should retain air for at least two hours without any leakage.

If the tire is unable to do so, it may require some additional sealant or re-checking the sealing tape and valve. Taking the time to check the sealing and air retention of your tubeless tire properly can save you from any potential accidents on the road.

FAQs

What is a tubeless tire and how does it work?

A tubeless tire is a type of tire that does not require an inner tube and the air is sealed within the tire itself. The tire bead sits snugly against the rim creating an airtight seal.

What can cause a tubeless tire to not seal on the rim?

There are several things that can cause a tubeless tire to not seal on the rim such as inadequate rim tape, damaged tire or rim, excess lubrication, or not enough sealant.

How can I tell if my tubeless tire is not sealed on the rim?

You can tell if your tubeless tire is not sealed on the rim if you hear a hissing sound or see air bubbles coming from the tire, or if the tire loses pressure even after it has been inflated.

Can I inflate a tubeless tire that is not sealed on the rim?

Yes, you can inflate a tubeless tire that is not sealed on the rim, but it will not hold air pressure for long. It is important to first identify the cause of the issue and address it before reinflating the tire.

How do I fix a tubeless tire that is not sealing on the rim?

To fix a tubeless tire that is not sealing on the rim, you will need to identify the cause of the issue and address it. This may include adding more sealant, replacing the rim tape, or fixing any damage to the tire or rim.

What is the proper way to inflate a tubeless tire?

The proper way to inflate a tubeless tire is to use a tubeless-specific floor pump or an air compressor with a tubeless-specific chuck. Make sure to monitor the pressure and not overinflate the tire.

Can I convert a standard tire to a tubeless tire?

Yes, you can convert a standard tire to a tubeless tire by using a tubeless conversion kit that includes rim tape, sealant, and a tubeless valve stem. However, it is important to note that not all tires are compatible with tubeless conversion.