Have you ever struggled with removing a tire from its rim? It can be a difficult and time-consuming process, especially if done manually. Fortunately, with the help of a tire machine, this task becomes much easier. The machine is designed to remove the tire from its rim quickly and efficiently, saving you time and energy.

A tire machine is a specialized tool used by mechanics and tire shops to remove and mount tires. It uses a combination of mechanical and hydraulic power to grip the tire firmly and separate it from the rim. The machine is designed to work with different tire sizes and can handle both aluminum and steel rims.

Using a tire machine is a straightforward process. First, the tire is placed on the machine and secured in place with the use of clamps. The machine is then set into motion, and the bead of the tire is gradually separated from the rim.

Once the tire is fully separated, it can be removed from the machine, and the rim is ready to be fitted with a new tire. By using a tire machine, the process of removing a tire from its rim becomes much more manageable. It saves time and energy, allowing you to focus on other tasks.

It is also a safer option since the machine reduces the risk of injury from manually attempting to remove the tire. In conclusion, if you have struggled with removing a tire from its rim, it may be time to invest in a tire machine. This specialized tool makes the process quicker and more manageable, saving you time and energy.

If you work in a tire shop or are a mechanic, a tire machine is an essential piece of equipment that can improve your efficiency and productivity.

Table of Contents

Gathering Necessary Equipment

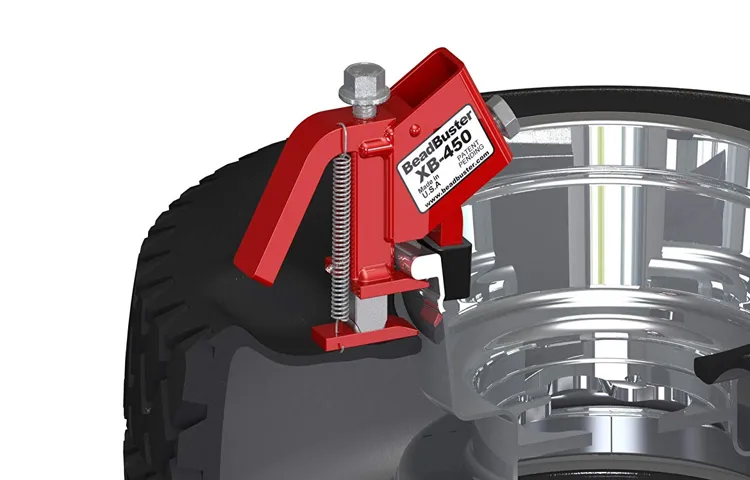

If you need to remove a tire from a rim with a machine, it’s important to gather the necessary equipment beforehand. The most essential item you’ll need is a tire-changing machine, which can vary in complexity and price depending on your needs and budget. In addition to the machine, you’ll also need a set of tire irons or bead breakers to help separate the tire from the wheel.

It’s important to use the right tools for the job, as using incorrect or poorly designed equipment can not only damage the tire and rim but also pose a safety hazard. Depending on the specifics of your tire and rim, you may also need other specialized tools or equipment, such as valve stem pullers or wheel protectors. To ensure a smooth and successful tire change, take the time to research the equipment you’ll need and invest in high-quality tools that are designed for the job at hand.

Machine Specification

When it comes to starting a new project, having the right equipment is crucial for its success. The same goes for machine learning, where selecting the appropriate hardware is essential for optimal performance. Gathering necessary equipment for machine learning includes a desktop computer with high-speed processing capabilities, adequate storage, ample memory, and a powerful graphics card to support complex algorithms.

It’s also essential to have software such as Python, R, and TensorFlow frameworks installed to run models effectively. Additionally, Jupyter Notebook, Spyder, and PyCharm can help streamline the development process. These tools are fundamental to a machine learning project’s overall success and can make or break its performance and results.

Thus, investing in high-quality equipment and software will ensure that the machine learning project is off to a good start.

Safety Gear

When it comes to staying safe during any activity, it’s crucial to have the right equipment. Whether you’re engaging in a high-risk sport or just exploring the outdoors, proper safety gear can make all the difference. Start by determining what type of activity you’ll be doing and what risks you may encounter.

For example, if you’ll be biking, a helmet is a must-have, while if you’re rock climbing, you’ll need climbing shoes and a harness. Don’t forget to also consider any environmental factors, such as weather or terrain. It’s always better to be over-prepared than under-prepared.

So, take the time to gather all the necessary safety equipment before heading out on your adventure. Remember, your safety is in your hands, and investing in proper safety gear is investing in yourself.

Loosening the Tire

Removing a tire from the rim can be a daunting task, especially if you don’t have the right tools. One way to remove the tire from the rim with a machine is to first loosen the tire. Start by positioning the wheel on the tire machine and then remove the valve core using a valve core remover tool.

This will release the air pressure from the tire. After that, use the tire machine to break the bead of the tire from the rim. This can be done by turning the machine’s mounting arm downwards to press the tire’s sidewall and break the seal with the rim.

Once the bead has been broken, use the tire machine’s bead loosener to remove the tire from the rim. This process can be accomplished by pushing the loosener against the rim of the wheel. With the tire loosened from the rim, you can now safely proceed with the next steps of changing a tire or replacing a damaged tire.

It’s important to note that these steps should be done cautiously, and protective gear should be worn to prevent any injuries.

Secure the Rim

If you’re an avid cyclist, you know the importance of checking your bike’s components before hitting the road. One of the most critical areas to inspect is the rim, specifically the tire. Over time, tires can loosen and cause various issues, such as decreased handling and increased chance of blowouts.

To avoid these hazards, secure the rim by checking the tire’s pressure regularly. Use a tire gauge to ensure it meets the manufacturer’s recommended pressure, and make adjustments as needed. Additionally, inspect the tire’s tread for wear and replace it if necessary.

By taking these steps, you can enjoy a smoother and safer ride, whether you’re hitting the trails or cruising the city streets.

Position the Machine

Loosening the tire is an essential step when positioning the machine. This helps to prevent any accidents and also ensures that the tire is installed correctly. To start, make sure that the machine is parked on a flat and stable surface.

Next, locate the lug nuts that hold the tire in place, and use the lug wrench to loosen them. Take care not to fully remove the lug nuts at this point, simply loosen them until they are easy to unscrew later. Once all of the lug nuts have been loosened, use a jack to lift the tire off the ground.

This will make it easier to remove the lug nuts completely and take the tire off. Remember to keep the lug nuts in a safe place, so they don’t get misplaced. With the tire off, you can then proceed to position the machine as required.

By following these steps, you can rest assured that you’re taking the necessary precautions to keep yourself and others safe while working on your machinery.

Release Air from the Tire

If you’ve ever had to change a flat tire, you know how important it is to release the air from the tire before you begin. To do this, you’ll need a tire valve stem tool or a small screwdriver. First, locate the valve stem – it’s usually a small metal or rubber tube that sticks out from the rim of the wheel.

Then, use the tool or screwdriver to press down on the valve stem’s center pin. You should hear a hissing noise as the air begins to escape. Keep holding it down until you no longer hear any air escaping.

It’s important to release all of the air from the tire before attempting to change it, as it will make it easier to remove and replace. Make sure to only release the air from the flat tire and not any of the other tires that are still inflated. By releasing the air properly, you can make changing a tire a smoother and safer process.

Removing the Tire

Removing a tire from a rim can be a daunting task, but with the right tools and procedure, it can be done quickly and efficiently. A tire machine is an ideal tool for removing tires from rims. Start by deflating the tire completely before placing it on the tire machine.

The next step is to loosen the lug nuts and remove the tire from the car. Once the tire is secured to the machine, position the mounting arm near the tire, and adjust the arm’s height to hold the tire securely in place. Turn the machine on, and use the pedal to expand the tire so that it releases from the rim.

Be sure to work gradually to avoid damaging the tire or rim. Once the tire is removed from the rim, use a tire iron to pry off the tire, starting at the valve stem. With a little leverage, the tire should pop off easily.

Repeat this process for the other side of the tire until it’s completely removed from the rim. Finally, after cleaning the rim and preparing the new tire, follow the same process in reverse to mount the new tire onto the rim.

Line-up the Beads

When it comes time to change a tire, you may find yourself struggling to get the old one off. One common issue is that the tire might feel “stuck” on the rim of the wheel. This is where “line-up the beads” comes in.

The beads are the edges of the tire that sit on the rim. Sometimes, these beads can get wedged into place or become difficult to dislodge. To remove the tire, you’ll need to align these beads with the center of the rim and then use a tire lever or other tool to break the seal between the tire and the rim.

Once this seal is broken, you should be able to slide the tire off with ease. Remember to be patient – rushing the process can damage the tire or even cause injury. With a little care and attention, you can tackle this task with confidence.

Turn on the Machine

When it’s time to remove a tire, you may feel like it’s a daunting task. However, with the right tools and a clear understanding of the process, it can be done quickly and easily. The first step is to turn on the machine and engage the locking mechanism to ensure the vehicle is secure.

Next, it’s time to remove the hubcap or center cap, depending on the type of vehicle you have. Once this is done, locate the lug nuts and use a lug wrench to loosen them. It’s important to remember to loosen the lug nuts before lifting the vehicle, as it can be a challenging task once the weight of the car is on the tire.

After the nuts are loosened, it’s time to lift the car using a jack. Once the car is safely lifted, remove the lug nuts and the tire. Now the tire is ready to be inspected, repaired, or replaced.

Remember to always use caution and follow the manufacturer’s instructions to ensure safety and success.

Removal Process

Removing a tire can be intimidating, but with the right tools and steps, it can be an easy task. First, make sure that the car is placed securely on a flat surface, with the emergency brake on and the gear in park. Then, use a lug wrench to loosen the lug nuts on the tire.

Once all the lug nuts are loosened, you can then jack up the car using a car jack. Make sure you place the jack on the correct location as indicated in your car manual to avoid damaging the car. Once the car is elevated enough, you can now completely remove the lug nuts and gently pull the tire off.

If the tire won’t budge, you can give it a gentle kick or spray some penetrating oil to loosen it. Remember to be careful when handling the tire and avoid injuring yourself. Following these steps will ensure a proper removal process that’s both safe and efficient.

Safety Precautions

Removing a tire from a rim with a machine can be a daunting task, especially if you don’t know the proper safety precautions to take. First off, make sure you’re wearing the proper protective gear such as safety glasses and gloves. It’s also a good idea to make sure the machine you’re using is in good working condition and that you’re familiar with its operation.

Before you start, inspect the tire and the rim for any damage or defects that could cause an accident. Once you’re ready to begin, position the machine and the tire in a stable and secure manner, and ensure that everything is properly aligned. It’s important to use the machine’s controls carefully and slowly to prevent any mishaps or injuries.

And finally, always be aware of your surroundings and keep other people out of the immediate area to avoid accidents. By following these safety precautions, you can remove a tire from a rim with a machine efficiently and safely.

Post-Removal Inspection

When it comes to post-removal inspections, safety precautions should always be a top priority. Before starting the inspection process, it’s important to ensure that the vehicle is securely placed on a level surface and turned off completely. This will prevent any accidents or injury that could occur if the vehicle were to move unexpectedly.

It’s also important to wear protective gear such as gloves and safety goggles to protect against any potential hazards. Checking for leaks and loose parts requires a careful eye and a steady hand, so always take your time and proceed with caution. Remember, safety first! By taking the necessary precautions during post-removal inspections, you can ensure both your safety and the reliability of the vehicle.

Conclusion

Removing a tire from a rim can be a daunting task that requires precision and patience. Luckily, with the right machine, this process can be made easy and efficient. Whether you are a seasoned mechanic or a DIY enthusiast, a tire changing machine can make the difference between a job well done and a frustrating and time-consuming experience.

So next time you need to remove a tire, remember to invest in the right tool and let the machine do the heavy lifting for you. Your fingers (and sanity) will thank you!”

FAQs

What machine can be used to remove a tire from a rim?

A tire changer or tire mounting machine can be used to remove a tire from a rim.

Can a tire be removed from a rim without a machine?

Yes, it is possible to remove a tire from a rim without a machine, but it can be difficult and may require special tools.

How does a tire changer work to remove a tire from a rim?

A tire changer uses a combination of mechanical force and specialized clamps to gently pry the tire away from the rim.

Are there any safety concerns when using a tire changer to remove a tire from a rim?

Yes, it is important to follow proper safety procedures when using a tire changer, such as wearing gloves and eye protection, and following the manufacturer’s instructions.

Can a tire be damaged during the process of removing it from a rim?

Yes, it is possible for a tire to be damaged if too much force is applied during the removal process, which is why it is important to use a suitable machine and follow safety procedures.

How long does it typically take to remove a tire from a rim using a machine?

The time it takes to remove a tire from a rim using a machine can vary, but typically it takes between 10-20 minutes.

Can a tire be re-used after it has been removed from a rim?

Yes, a tire can be re-used after it has been removed from a rim, as long as it is not damaged and is properly re-mounted onto a new rim using a tire changer or similar machine.