Have you ever experienced a flat tire in the middle of nowhere? It’s a frustrating situation, especially when you realize that the tire is tubeless and needs to be sealed to the rim. But don’t worry, sealing a tubeless tire to the rim is not as complicated as it may seem. With the right tools and techniques, you can seal a tubeless tire to the rim quickly and easily, ensuring that it stays in place and doesn’t get punctured again.

In this blog post, we will guide you through the process of sealing a tubeless tire to the rim, along with some useful tips and tricks to make it a hassle-free experience. So, get ready to become a pro at sealing tubeless tires!

Gather Necessary Tools

When it comes to sealing a tubeless tire to a rim, you will need the proper tools to get the job done right. Some of the tools you’ll need include a valve removal tool, sealant injector, tire levers, a floor pump or air compressor, and of course, the tubeless sealant itself. The valve removal tool is necessary to remove the valve core from your tire valve so you can inject the sealant into the tire.

The sealant injector will allow you to easily apply the sealant into the tire. Tire levers will help you remove the tire from the rim if necessary, and the floor pump or air compressor will provide the necessary air pressure to seat the tire onto the rim. Make sure to choose the right type of sealant for your specific tire and rim to ensure the best performance and longevity.

With these tools in hand, you’ll be able to seal your tubeless tire to the rim with ease and know that you’re ready to hit the road or trail with confidence.

Tools Needed for Sealing

When it comes to sealing, having the right tools can make all the difference. The first thing you’ll need is a caulking gun, which is used to apply the sealant in a controlled and precise manner. You’ll also need a utility knife or a razor blade to cut the tip of the caulking tube.

An old rag or sponge will be handy for wiping away any excess sealant and smoothing out the surface. If you’re working on a vertical surface, a ladder or a step stool will help you reach the higher areas. It’s important to wear protective gloves to avoid getting sealant all over your hands.

Having a drop cloth or newspaper spread out beneath your work area will help keep the mess to a minimum. With these tools on hand, you’ll be well-equipped to tackle any sealing job with confidence and ease.

Remove Tire and Clean Rim

If you want to seal a tubeless tire to a rim, removing the tire and cleaning the rim is an essential first step. This will ensure that you have a clean surface to work with and that there is no debris that could interfere with the seal. Start by deflating the tire completely and releasing any remaining air pressure from the valve.

Then, use tire levers to remove the tire from the rim, being careful not to damage the tire or the rim in the process. Once the tire is removed, you’ll want to use a cleaning solution to remove any residue or dirt from the rim. This will help create a seal that won’t leak air.

Use a clean, dry cloth to dry the rim before moving on to the next step. With a clean and dry rim, you’re ready to move on to the next step in sealing your tubeless tire to the rim.

Removing and Cleaning the Tire

When it comes to removing and cleaning a tire, there are a few important steps you need to follow. First, you’ll want to use a wrench to loosen the lug nuts on the wheel. Once they are loose, you can use a jack to lift the vehicle and remove the tire completely.

This will give you access to the rim, which you can then clean thoroughly. It’s important to remove any dirt, grime, or debris from the rim to ensure a good fit when you put the tire back on. You can use a mild soap and water, along with a scrub brush, to get the job done.

Once the rim is clean, you’ll want to inspect it for any damage or wear and tear. If there are any issues, you may need to have the rim repaired or replaced before you put the tire back on. Overall, taking the time to remove and clean your tire properly will help ensure your safety and prolong the life of your tire.

Insert Sealant

If you’re wondering how to seal a tubeless tire to the rim, the first step is to insert sealant. Tubeless tires use a liquid sealant to prevent air leaks through the rim and around the tire bead. To insert the sealant, remove the valve core and pour the recommended amount of sealant into the tire through the valve stem.

Next, rotate the wheel to distribute the sealant evenly. Make sure to reinstall the valve core and inflate the tire to the recommended pressure. It’s important to note that sealant needs to be replaced every few months or after any significant puncture to ensure optimal performance.

By properly inserting and maintaining sealant, you’ll be able to enjoy the benefits of tubeless tires, including improved traction and reduced risk of flat tires.

How to Add Sealant to Tire

Adding sealant to a tire can help prevent flat tires and prolong the life of your tires. The process of adding sealant to a tire is relatively simple and can be done at home with the right tools and materials. The first step is to remove any debris from the tire, such as rocks or nails, and ensure that the tire is fully inflated.

Next, you will need to remove the valve stem core to allow for the sealant to be added to the tire. Once the valve stem core has been removed, insert a tube into the tire and add the sealant according to the manufacturer’s instructions. It is important to replace the valve stem core and inflate the tire to the recommended pressure after adding the sealant.

In no time, you’ll have a tire that’s well-protected from potential flat tires and that can withstand more wear and tear on the road. So, don’t hesitate to add sealant to your tire to keep it running smoothly for longer!

Reinstall Tire onto Rim

When it comes to tubeless tires, ensuring that good seal is formed between the tire and the rim is essential. If you need to reinstall a tire onto a rim, you’ll want to follow some key steps to make sure you get a proper seal. First, thoroughly clean both the tire and the rim to remove any dirt, debris, or old sealant.

Next, apply a layer of fresh sealant to the rim, making sure it completely covers the area where the bead of the tire will sit. Once that’s done, carefully position the tire onto the rim, making sure the bead is seated properly. Use a tire lever or a compressor to help you get the tire in place, and make sure everything is securely in place before reinflating the tire.

With the right technique, you’ll be able to seal your tubeless tire to the rim and get back on the road in no time!

How to Properly Reinstall Tire

When it comes to reinstalling a tire onto a rim, it’s important to take the proper steps in order to ensure a secure and stable fit. First, inspect the tire and rim for any damage or debris that may affect the reinstallation process. Once the tire has been deemed safe to reinstall, start by aligning the tire with the rim and gently pressing the tire onto the rim, starting at the valve stem.

Work your way around the rim, pressing down firmly to ensure the tire bead is seated properly. Use a tire iron to finish the installation, tightening the lug nuts in a star pattern to ensure even distribution of pressure. It’s important to never overinflate the tire and to always double-check the tightness of the lug nuts before hitting the road.

By following these simple steps, you can ensure a safe and successful tire installation every time.

Test for Leaks

If you’re a rider, you may have experienced a flat tire during a ride. It can be a hassle and downright dangerous, which is why it’s important to know how to seal a tubeless tire to the rim. There are a few methods for sealing tubeless tires, but the most popular is using sealant.

First, ensure that your rim and tire are clean and dry. Then, apply sealant to the tire through the valve stem, making sure to distribute it evenly. Once the sealant is in, inflate the tire and shake it side-to-side to ensure the sealant is evenly distributed.

After that, the tire should be ready to ride. It’s important to test for leaks after sealing the tire by letting the tire sit for a few hours or overnight and checking for any signs of leakage. With this quick and easy method, you’ll be back on the road in no time.

How to Check for Tire and Rim Leaks

If you suspect that your tires or rims are leaking, the first step is to perform a leak test. There are several ways to do this, but one common method is to apply a soapy water solution to the suspected area and look for bubbles. Another option is to use a tire pressure gauge to check for a significant drop in pressure over a short period of time.

Once you have identified the source of the leak, it’s important to have it repaired as soon as possible to avoid further damage to your vehicle or potential safety hazards on the road. Regularly inspecting your tires and rims for leaks can save you money and prevent more serious problems down the road. So don’t hesitate to take action if you suspect there is a problem with your tires or rims.

Remember, prevention is the best defense against unexpected breakdowns and costly repairs.

Additional Tips and Tricks

If you’re struggling to seal your tubeless tire to a rim, don’t worry, there are some additional tips and tricks you can try. First, make sure your rim and tire are clean and free of debris. Then, apply a generous amount of sealant to the inner rim and tire bead.

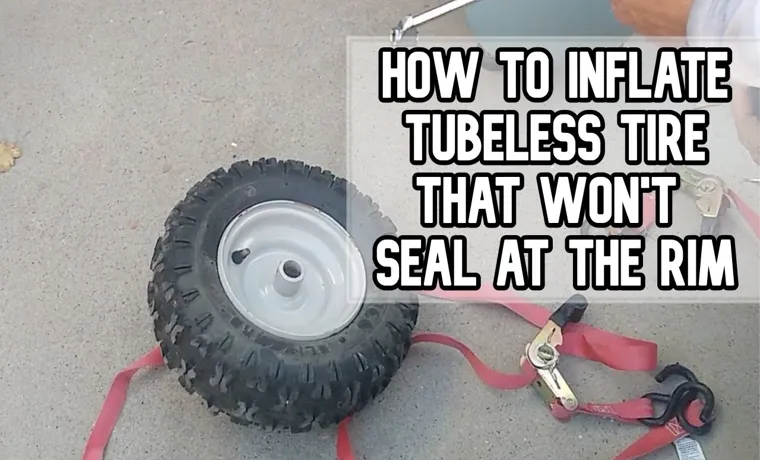

You can also try shaking or bouncing the tire to distribute the sealant evenly. If the tire still won’t seal, try using a high-pressure air compressor to force the bead onto the rim. You can also try using a tubeless tire booster to get a strong burst of air pressure.

If all else fails, try using a bead jack to manually push the tire onto the rim. With these tips in mind, you should be able to properly seal your tubeless tire to your rim and enjoy a smooth, hassle-free ride.

Conclusion

In conclusion, sealing a tubeless tire to a rim is like sealing the deal on a business partnership – it requires the right tools, attention to detail, and a bit of finesse. By following the steps outlined above, you can ensure a tight and secure seal between your tire and rim, protecting against leaks and blowouts. So, go forth and conquer the road with confidence, knowing that you’ve sealed the deal on your tire and rim relationship.

“

FAQs

What causes air to leak from tubeless tires?

Air can leak from tubeless tires due to punctures, worn-out valve stems or rims, and improper tire seating.

Can I seal a tubeless tire to the rim with standard tire sealant?

Yes, you can use standard tire sealant to seal a tubeless tire to the rim. However, it is recommended to use a sealant specifically designed for tubeless tires.

What is the best way to clean the rim before sealing a tubeless tire?

The best way to clean the rim before sealing a tubeless tire is to use a wire brush or sandpaper to remove any dirt, rust, or debris that may prevent proper sealing.

How long does it take for tubeless tire sealant to set?

It usually takes between 5 to 10 minutes for tubeless tire sealant to set. However, it may take longer or shorter depending on the type of sealant used and the severity of the puncture.

Can tubeless tire sealant damage the tire or the rim?

Tubeless tire sealant can potentially damage the tire or the rim if used improperly or in excessive amounts. Therefore, it is important to follow the manufacturer’s instructions carefully.

What should I do if sealant fails to seal a tubeless tire?

If sealant fails to seal a tubeless tire, you may need to replace the tire or take the vehicle to a professional tire repair shop for further diagnosis and repair.

Can tubeless tires be sealed without removing them from the rim?

Yes, tubeless tires can be sealed without removing them from the rim using a sealant injection tool or a valve core removal tool depending on the type of sealant used.