Hey there! Have you ever given any thought to the coolant in your car? It may not be the most glamorous part of vehicle maintenance, but it plays a crucial role in keeping your engine running smoothly. In fact, testing coolant is an important step in ensuring the longevity and performance of your car. Think of it as the lifeblood of your engine, constantly working to regulate its temperature and prevent overheating.

Just like regular check-ups at the doctor, testing your coolant can help you catch any potential issues before they become major headaches. So, why is testing coolant so important? Let’s dive in and find out.

Table of Contents

- 1 What is Coolant?

- 2 Why is Testing Coolant Important?

- 3 Visual Inspection

- 4 pH Testing

- 5 Freezing Point Testing

- 6 Conductivity Testing

- 7 Corrosion Monitoring

- 8 Regular Coolant Testing is Essential for Vehicle Maintenance

- 9 Testing Coolant Helps Prolong the Life of Your Engine

- 10 Follow the Manufacturer’s Guidelines for Coolant Testing

- 11 Conclusion

- 12 FAQs

What is Coolant?

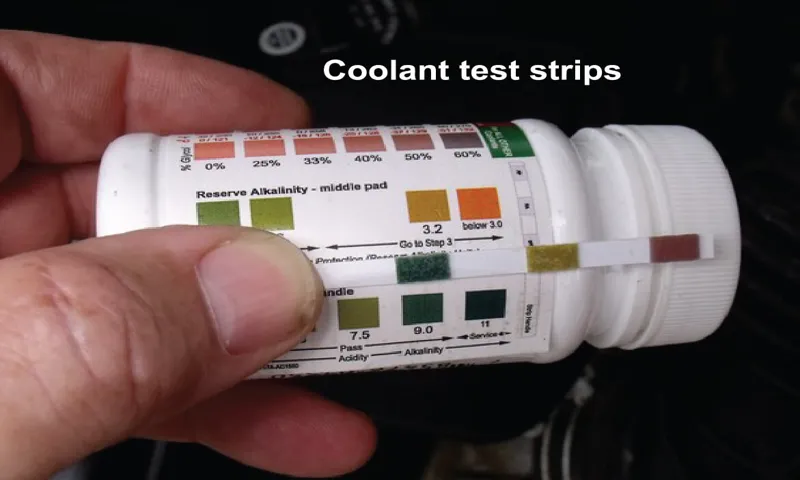

Coolant, also known as antifreeze, is an essential fluid used in the cooling system of a vehicle. It helps regulate the temperature of the engine by absorbing heat and transferring it away. But how do you know if your coolant is still effective? A simple way to test your coolant is by using a coolant test strip.

These strips measure the pH level, freeze point, and if there are any contaminants present in the coolant. By using a test strip, you can quickly determine if your coolant needs to be replaced or if it’s still in good condition. It’s important to regularly test your coolant to ensure optimal performance of your vehicle’s cooling system and to prevent any potential damage to the engine.

So, the next time you’re unsure about the quality of your coolant, grab a test strip and check it out!

Why is Testing Coolant Important?

When it comes to maintaining your vehicle, testing coolant is a crucial step that should not be overlooked. Coolant, also known as antifreeze, plays a vital role in keeping your engine from overheating and preventing engine damage. Regularly testing coolant ensures that it is still providing the necessary protection for your engine.

But how do you test coolant? One way is to use a coolant tester, which measures the specific gravity of the coolant. This measurement indicates the freeze point and boiling point of the coolant, allowing you to determine if it needs to be topped up or replaced. Testing coolant is an important part of routine vehicle maintenance and can help you avoid costly repairs down the road.

So, next time you’re checking your vehicle’s fluids, don’t forget to test your coolant!

Hey there! Are you wondering about the different methods for testing your coolant? Well, you’ve come to the right place. Testing coolant is essential to ensure the proper functioning and longevity of your vehicle’s engine. Without proper coolant, your engine can overheat, leading to potential damage and costly repairs.

Think of coolant as your engine’s best buddy, working hard to keep it cool and happy. And just like any friendship, you need to check in on it once in a while to make sure it’s doing its job effectively. But how exactly do you test coolant? There are several methods you can use to check the condition and quality of your coolant.

One common method is to use a coolant tester or hydrometer. This nifty tool measures the specific gravity of your coolant, indicating its freezing and boiling points. By knowing these points, you can ensure that your coolant will protect your engine in extreme temperatures.

Another method for testing coolant is by using test strips. These strips are dipped into the coolant, and after a few seconds, they change color to indicate the presence of certain contaminants such as oil, dirt, or exhaust gases. By identifying these contaminants, you can take the necessary steps to flush and replace your coolant, ensuring optimal engine performance.

If you’re not a fan of tools or test strips, fear not! There’s a more straightforward method called the visual inspection. This method involves visually inspecting your coolant for any signs of discoloration, dirt, or debris. A clean and clear coolant indicates that everything is A-OK, while a murky or dirty coolant may signal the need for a change.

So, whether you prefer a gadget, a quick strip test, or a good old-fashioned visual inspection, there are plenty of methods for testing your coolant. The key is to regularly check and maintain your coolant to keep your engine running smoothly and avoid any surprises down the road. Stay tuned for our upcoming blog posts, where we’ll dive deeper into each testing method and provide you with expert tips and advice.

Visual Inspection

One important aspect of maintaining your vehicle’s cooling system is regularly checking the coolant level. So, how do you test the coolant in your car? Well, the first step is to visually inspect the coolant reservoir. This is usually a translucent plastic container located near the radiator.

Make sure the engine is cool before opening the reservoir cap. Open the cap slowly and check the coolant level. It should be between the minimum and maximum marks on the side of the reservoir.

If the level is low, you will need to add more coolant. But before doing so, make sure to check for any leaks or signs of damage in the cooling system. If everything looks good, you can top up the coolant using a coolant mixture recommended by your vehicle’s manufacturer.

Regularly checking the coolant level and maintaining it at the proper level will help prevent overheating and potential engine damage.

Checking for Contamination

visual inspection, contamination, quality control When it comes to checking for contamination in a product, visual inspection is an important tool in the quality control process. In this step, trained technicians carefully examine the product to identify any visible signs of contamination. This can include things like dirt, debris, or foreign objects that may have found their way into the product during manufacturing or packaging.

By performing a thorough visual inspection, companies can ensure that their products meet the highest standards of quality and safety. This step is especially important in industries such as food and pharmaceuticals, where even the smallest amount of contamination can have serious consequences. So, the next time you open a package of food or take a medication, remember that it has likely undergone a rigorous visual inspection to ensure your safety and satisfaction.

Checking for Sediment or Deposits

sediment or deposits, visual inspection

Checking for Color

“Checking for Color”

pH Testing

If you’re experiencing problems with your vehicle’s cooling system, it may be necessary to test the coolant. Testing the pH level of the coolant can provide important information about its acidity or alkalinity, which can affect the overall performance of the cooling system. To test the coolant pH, you’ll need a pH testing kit, which can be easily purchased at an auto parts store or online.

Once you have the kit, simply follow the instructions provided to collect a sample of the coolant and test its pH level. This can help you determine if the coolant needs to be flushed and replaced, or if there are any underlying issues with the cooling system that need to be addressed. Testing the coolant pH regularly can help keep your vehicle running smoothly and prevent any long-term damage to the engine.

So, what are you waiting for? Grab a pH testing kit and start testing your coolant today!

What is pH?

pH is a term that you might have heard in your chemistry class or while shopping for skincare products. But what exactly is pH and why is it important? Well, pH is a measure of how acidic or alkaline a substance is. It is represented on a scale from 0 to 14, with 7 being neutral.

Anything below 7 is considered acidic, while anything above 7 is alkaline. pH testing is the process of determining the pH level of a substance, whether it be a liquid or a solid. pH testing is used in various fields, including chemistry, biology, and even in our everyday lives.

Have you ever wondered why some fruits taste sour while others taste sweet? The answer lies in their pH levels. Sour fruits like lemons and oranges have a low pH, making them acidic, while sweet fruits like bananas and strawberries have a higher pH, making them alkaline. pH testing also plays a crucial role in maintaining the health of our bodies.

Our stomachs, for example, have a low pH to help break down the food we eat. Similarly, the pH level of our skin affects its overall health and appearance. Using skincare products with the right pH balance can help keep our skin looking its best.

In conclusion, pH testing is an important tool that helps us understand and measure the acidity or alkalinity of substances. It is used in various fields and has a significant impact on our everyday lives. By understanding pH, we can make informed choices and maintain a healthy balance in our bodies and the world around us.

How to Test Coolant pH

coolant pH, pH testing, testing coolant pH

Interpreting the Results

When it comes to interpreting the results of pH testing, there are a few key things to consider. pH testing is used to measure the acidity or alkalinity of a substance, and the results can provide valuable insights into the health and safety of various environments. One important aspect to keep in mind is that pH is measured on a scale from 0 to 14, with 7 being considered neutral.

A pH value below 7 indicates acidity, while a value above 7 indicates alkalinity. The interpretation of the results will depend on the specific context in which the testing is being done. For example, in a water testing scenario, a pH value below

5 could suggest the presence of acid rain or pollution. On the other hand, in a pool testing scenario, a pH value of 2 to

8 is considered optimal for swimmer comfort and water balance. It’s also important to remember that pH is not the only factor to consider when assessing the quality of a substance. Other factors such as temperature, dissolved oxygen, and nutrient levels can also influence the overall health and safety of an environment.

So, while the results of pH testing can provide valuable information, it’s essential to consider other factors and interpret the results in the appropriate context.

Freezing Point Testing

If you’re wondering how to test your coolant to ensure it will protect your engine from freezing, you’ve come to the right place! Testing the freezing point of your coolant is essential, especially during the colder months. The process is relatively simple and can be done using a hydrometer or a refractometer. First, make sure your engine is cool and the coolant level is at the proper level.

Then, take a small sample of the coolant from the radiator or overflow tank using a clean container. Next, insert the hydrometer or refractometer into the coolant sample and read the scale to determine the freezing point. If the freezing point is not within the recommended range, it may be time to replace or add coolant.

Regular testing of your coolant will help ensure that your engine stays protected during freezing temperatures.

Why is Freezing Point Important?

freezing point, freezing point testing

How to Test Coolant Freezing Point

coolant freezing point, test coolant, freezing point of coolant Paragraph: Have you ever wondered how to test the freezing point of your coolant? It’s actually quite simple! Testing the freezing point of coolant is essential to ensure that it will still provide sufficient protection and performance in extremely cold temperatures. One way to test the freezing point is by using a refractometer. This handy tool allows you to measure the concentration of the coolant, which can then be used to determine its freezing point.

Alternatively, you can also use a hydrometer to test the specific gravity of the coolant. By comparing the reading to a chart specific to your coolant type, you can determine the freezing point. So next time you want to make sure your coolant can withstand the winter chill, give one of these methods a try and stay protected on the road!

Interpreting the Results

In the process of testing freezing points, it is important to understand and interpret the results accurately. Freezing point tests are commonly used in various industries such as food production, pharmaceuticals, and automotive to determine the purity and quality of substances. These tests involve cooling a sample and observing the temperature at which it solidifies.

The freezing point can provide valuable insights into the composition and properties of the substance being tested. When interpreting the results, it is essential to consider factors such as the accuracy of the testing equipment, the conditions under which the test was conducted, and any potential impurities or contaminants present in the sample. Additionally, it is important to compare the obtained freezing point with known values for the substance in question, as well as with other relevant data.

One key aspect to consider is the accuracy of the testing equipment. High-quality instruments that are properly calibrated can produce more reliable and accurate results. It is also important to note any potential sources of error or variability in the testing process.

For example, variations in cooling rate or in the size and shape of the sample can affect the observed freezing point. Another crucial factor to consider is the presence of impurities or contaminants in the sample. Impurities can lower the freezing point of a substance, making it appear to have a lower purity than it actually does.

It is necessary to account for these impurities and make appropriate adjustments in the interpretation of the results. Comparing the obtained freezing point with known values for the substance is also vital. Thermodynamic data for various substances are available in databases, and these values can serve as benchmarks for comparison.

If the observed freezing point deviates significantly from the expected value, it may indicate a potential issue with the sample or the testing process. In conclusion, interpreting freezing point test results requires careful consideration of various factors, including the accuracy of the testing equipment, any impurities or contaminants present in the sample, and the comparison with known values. By taking these factors into account, accurate interpretations can be made, leading to valuable insights into the composition and quality of the substance being tested.

Conductivity Testing

If you’re wondering how to test coolant, one important factor to consider is its conductivity. Conductivity testing is used to measure the ability of coolant to conduct electricity. This is important because the conductivity of coolant can affect its ability to dissipate heat.

Coolant with low conductivity may not be as effective at transferring heat away from the engine, potentially leading to overheating. On the other hand, coolant with high conductivity may indicate the presence of contaminants or improper mixing. To test coolant conductivity, you will need a conductivity meter or tester.

Simply dip the conductivity probe into the coolant and the meter will provide a reading. If the conductivity is within the manufacturer’s recommended range, your coolant should be in good condition. If it falls outside the recommended range, it may be time to change your coolant or investigate further for any issues.

So, next time you’re checking your coolant, don’t forget to test its conductivity to ensure optimal engine performance.

What is Conductivity?

conductivity testing, electrical conductivity, electrical current, conductivity measurement, conductivity meter, conductive materials, non-conductive materials, conductivity of water, electrical conductivity of metals, conductivity of solutions, conductivity units In the world of science and engineering, conductivity testing plays a vital role in understanding and analyzing the electrical properties of various materials. Conductivity refers to the ability of a material to transmit electrical current. It is a measure of how easily an electrical current can flow through a substance.

Conductivity testing involves the use of a conductivity meter, which measures the ability of a material to conduct electrical current. The meter is typically equipped with two electrodes, which are placed in contact with the material being tested. When an electrical current is applied to the electrodes, the meter measures the current flowing through the material.

Conductive materials, such as metals, have high conductivity and allow electrical current to flow easily. Non-conductive materials, on the other hand, have low conductivity and do not allow electrical current to flow easily. Conductivity testing is used in various industries and applications.

For example, in the field of water quality testing, conductivity measurement is used to determine the purity and mineral content of water. The conductivity of water can indicate the presence of dissolved salts and other impurities. In the field of metallurgy, conductivity testing is used to determine the electrical conductivity of metals.

This information is important in applications such as electrical wiring and circuit design. Conductivity testing is also used in chemistry and biology to measure the conductivity of solutions. This information can be used to understand the properties of various substances, such as the concentration of ions in a solution.

Conductivity is usually measured in units called siemens per meter (S/m). This unit represents the reciprocal of resistance and is a measure of the material’s ability to conduct electricity. In conclusion, conductivity testing is an important tool in understanding the electrical properties of various materials.

How to Test Coolant Conductivity

conductivity testing, coolant conductivity testing

Interpreting the Results

conductivity testing. Interpreting the results of conductivity testing can provide valuable insights into the properties of a material or substance. Conductivity is a measure of how well a substance can conduct electric current, and it is often used to assess the purity or concentration of a solution.

When interpreting conductivity test results, it is important to consider the context in which the test was conducted. For example, in the case of water, conductivity can be influenced by factors such as temperature, dissolved solids, and the presence of ions. Conductivity testing can be particularly useful in industries such as water treatment, where it can be used to monitor the quality of drinking water.

By interpreting the results of conductivity tests, professionals can identify and address any potential issues, ensuring the safety and efficiency of the processes involved. So, next time you hear about conductivity testing, remember that beyond raw data lies a wealth of information waiting to be uncovered.

Corrosion Monitoring

When it comes to monitoring coolant in industrial settings, testing for corrosion is an important process. Corrosion can lead to serious damage to equipment and affect the overall efficiency of the system. So, how can you test coolant for corrosion? One common method is to use test strips that can measure the pH levels of the coolant.

These strips are dipped into the coolant and the color change indicates the acidity or alkalinity of the coolant. Another method is to use corrosion coupons, which are small metal samples that are placed in the coolant system. These samples are periodically removed and examined for signs of corrosion.

Additionally, regular visual inspections and monitoring of the equipment can also help identify any signs of corrosion. By regularly testing coolant for corrosion, potential problems can be detected early on and appropriate actions can be taken to prevent further damage. So, don’t overlook the importance of corrosion monitoring – it could save you from costly repairs in the long run.

What is Corrosion Monitoring?

corrosion monitoring

How to Test Coolant for Corrosion

coolant, corrosion, test coolant for corrosion, corrosion monitoring

Interpreting the Results

corrosion monitoring, interpreting the results

Conclusion is a crucial part of any piece of writing. It is the part where you tie all your arguments together and make a final statement. It is the part where you leave the readers with a lasting impression and make them reflect on what they have just read.

But writing a strong conclusion is not as easy as it seems. It requires careful planning and consideration to ensure that you leave a lasting impact on your readers. In this blog post, we will dive deeper into the art of writing a powerful conclusion.

So, let’s get started and explore the various techniques and strategies that can help you write a conclusion that leaves a mark.

Regular Coolant Testing is Essential for Vehicle Maintenance

Regular coolant testing is essential for vehicle maintenance to ensure that your engine stays cool and performs optimally. Coolant, also known as antifreeze, plays a vital role in preventing your engine from overheating and freezing in extreme temperatures. Testing your coolant helps you determine if it still has the appropriate levels of additives and corrosion inhibitors, which can degrade over time.

Testing can also identify any contaminants, such as oil or dirt, that may have entered the cooling system. By regularly testing your coolant, you can catch any issues early on and prevent potential damage to your engine. So, how do you test your coolant? One way is to use an antifreeze tester, which measures the freezing and boiling points of the coolant.

This can help you determine if it needs to be replaced or if it still has sufficient protection. Another option is to send a sample of your coolant to a laboratory for analysis. They can test for pH levels, conductivity, and the presence of any contaminants.

This thorough testing can provide you with detailed information about your coolant’s condition and help you make informed decisions about maintenance and replacement. Overall, regularly testing your coolant is a simple and cost-effective way to ensure the longevity and performance of your vehicle’s engine.

Testing Coolant Helps Prolong the Life of Your Engine

If you want to prolong the life of your engine, it’s important to regularly test your coolant. Coolant, also known as antifreeze, plays a crucial role in maintaining the temperature of your engine and preventing it from overheating. Over time, coolant can become contaminated with debris and lose its effectiveness.

By testing your coolant, you can ensure that it is still providing the necessary protection for your engine. Testing coolant is a relatively simple process that can be done at home or by a professional. One common method is to use a coolant testing strip, which will indicate the levels of various chemicals in your coolant.

Another option is to use a refractometer, which measures the freezing and boiling points of the coolant. By regularly testing your coolant, you can catch any issues early on and prevent costly damage to your engine. So, make sure to add coolant testing to your regular maintenance routine.

Follow the Manufacturer’s Guidelines for Coolant Testing

If you want to ensure that your coolant is performing at its best, it’s important to follow the manufacturer’s guidelines for coolant testing. Testing your coolant can help you identify any potential issues before they become major problems, saving you time and money in the long run. The manufacturer’s guidelines will provide you with specific instructions on how and when to test your coolant, as well as what methods and equipment to use.

This will ensure that you get accurate and reliable results. By regularly testing your coolant, you can not only monitor its performance but also detect any contaminants or other issues that may be affecting its effectiveness. So, don’t skip this important step – follow the manufacturer’s guidelines for coolant testing and keep your engine running smoothly.

Conclusion

In conclusion, testing coolant is like the ultimate chemistry experiment for your car’s cooling system. It’s like giving your engine a pop quiz to make sure it’s running at optimal efficiency. Think of it as coolant CSI – you’re investigating the scene for any signs of trouble and making sure your vehicle is squeaky clean.

So, grab your trusty test kit and channel your inner scientist. It’s time to delve into the mysterious world of coolant testing. Remember to follow the steps with precision and caution, as coolant is not to be taken lightly.

And if you’re feeling a bit overwhelmed, just think of yourself as the Sherlock Holmes of car care, on a mission to uncover any coolant mysteries. But why does testing coolant matter, you ask? Well, maintaining the proper balance of coolant is essential for your car’s health. It’s like giving it a refreshing spa treatment, ensuring that it stays cool under pressure.

By testing coolant, you’re not only preventing overheating issues but also safeguarding against corrosion and damage to vital engine parts. So, next time you find yourself gazing into that vibrant green or vivid blue liquid, remember that testing coolant is not just a chore – it’s an opportunity to become a coolant connoisseur. With the right tools and the right mindset, you’ll be able to diagnose any coolant conundrums and keep your engine purring like a contented kitty.

In the end, testing coolant is like the ultimate test of your car care skills. It’s a badge of honor, a testament to your commitment to keeping your vehicle running smoothly. So go forth, my fellow coolant testers, and let your inner car mechanic shine.

Your engine will thank you, and your friends will be in awe of your coolant knowledge. Stay cool, my friends!”

FAQs

How often should I test my coolant levels in my car?

It is recommended to test your coolant levels at least once a month to ensure proper maintenance of your vehicle’s cooling system.

What is the purpose of testing coolant?

Testing coolant helps to identify if there are any issues with the coolant’s composition, such as low or high pH levels, which could lead to engine overheating or damage.

How do I test the pH level of coolant?

To test the pH level of coolant, you can use a pH testing strip specifically designed for coolant. Simply dip the strip into the coolant and compare the color obtained with the pH chart provided to determine the pH level.

What should I do if the pH level of my coolant is too low?

If the pH level of your coolant is too low, which indicates acidity, you should add a coolant pH stabilizer or coolant additive recommended by your vehicle manufacturer to bring the pH level within the optimal range.

Can I use a regular pH test strip to test coolant?

It is not recommended to use a regular pH test strip to test coolant as coolant has different chemical properties compared to other substances. It is best to use a pH testing strip specifically designed for coolant.

Is there a specific temperature at which coolant should be tested?

There is no specific temperature at which coolant needs to be tested. However, it is advisable to test coolant when the engine is cool or has not been running for a while to avoid any potential burns or injuries.

How can I check if my coolant is contaminated?

One way to check if your coolant is contaminated is to visually inspect it for any signs of discoloration, debris, or oil residue. You can also use a coolant testing kit to check for contaminants such as oil or rust particles in the coolant.