Have you noticed a slight leak in your tire, but after inspecting it, you can’t seem to find any punctures or damage? The problem could be a loose valve stem, causing air to slowly escape from your tire. This issue may seem insignificant, but it can affect your tire’s performance and your safety on the road. Fortunately, tightening a tire valve stem is a straightforward procedure that can be done in a matter of minutes.

In this blog, we’ll show you how to tighten a tire valve stem properly, so you can prevent any potential problems and keep your vehicle in top shape.

What You Will Need

If you notice that the tire on your vehicle is losing air, especially when it hasn’t been punctured, the issue may lie with the tire valve stem. Before you start tightening it, you will need a few tools, such as a valve stem tool or pliers, a tire pressure gauge, and a valve stem cap. It’s important to choose the right type of valve stem tool for your tire valve stem, as different stems require different tools.

Make sure you have the right tool for the job before you start. Additionally, a tire pressure gauge will help you determine the right tire pressure for your vehicle, while a valve stem cap will keep the valve stem clean and prevent dust and debris from accumulating on it. Once you have all the necessary tools, you can begin the process of tightening your tire valve stem and ensuring that your tire stays properly inflated.

Tire pressure gauge

When it comes to checking your tire pressure, a reliable tire pressure gauge is an essential tool to have in your kit. You can easily purchase a tire pressure gauge at any auto parts store or online retailer. A standard gauge will measure tire pressure up to 50 PSI, but you may want to consider investing in a high-pressure gauge if you have a sports car or motorcycle with higher tire pressure requirements.

Additionally, it’s important to choose the right type of gauge for your needs, such as a digital or analog gauge. So, before you hit the road, make sure you have a reliable tire pressure gauge on hand to ensure your tires are properly inflated to improve fuel efficiency and keep you safe while driving!

Valve stem tool

If you’re a car enthusiast or a mechanic, having a valve stem tool in your arsenal is a must. This tool will help you quickly remove and install valve stems without damaging the valve or the valve stem itself. To use this tool, you’ll need a few things.

First, you need to have a valve stem tool. There are plenty of options on the market, so make sure to get one that is compatible with your car’s valve stems. Additionally, you’ll need to have some valve stems on hand.

You can purchase them at your local auto parts store or online. Finally, make sure you have a valve stem remover/installer tool. This tool will help you quickly and easily remove and install the valve stems.

With these tools in hand, you’ll be able to quickly perform routine maintenance on your vehicle and get back on the road in no time!

Pliers or adjustable wrench

When it comes to tackling household DIY projects, having the right tools is crucial. Two essential items that you will need are a pair of pliers and an adjustable wrench. Pliers are great for gripping, twisting, and cutting wires, while adjustable wrenches are ideal for tightening or loosening nuts and bolts.

Depending on the project, you may need one or both of these tools to get the job done efficiently. When selecting pliers, consider the type of work you will be doing. Needle-nose pliers are ideal for getting into tight spaces, while slip-joint pliers are better for larger jobs.

Similarly, when choosing an adjustable wrench, make sure that it is the right size for the job. A wrench that is too small can damage the nut or bolt, while one that is too large may not fit properly. With the right tools at your disposal, you can tackle even the most challenging DIY projects with confidence and ease.

Step 1: Check Tire Pressure

If you want to tighten your tire valve stem, the first step is to check your tire pressure. Low tire pressure can cause your tires to wear unevenly, reducing their lifespan and compromising your safety on the road. To check your tire pressure, you’ll need a tire pressure gauge, which you can buy at any auto parts store or online.

Simply remove the valve stem cap, press the gauge onto the valve stem, and wait for the reading. If the reading is below the recommended level listed in your car’s manual or on the tire placard, you’ll need to add air to your tires. Most gas stations have free air pumps, but you may want to invest in a portable air compressor if you plan on doing this frequently.

Once your tire pressure is at the proper level, you can move on to tightening the valve stem.

Use a tire pressure gauge to check the pressure in your tires.

Tire Pressure GaugeWhen it comes to maintaining your vehicle, it’s important not to neglect your tires. One crucial aspect of tire maintenance is ensuring that your tires are properly inflated. Driving on overinflated or underinflated tires can negatively affect your vehicle’s handling, fuel efficiency, and even your safety on the road.

To check your tire pressure, start by purchasing a tire pressure gauge from a local auto parts store or online retailer. Then, unscrew the valve cap from your tire and firmly press the gauge onto the valve stem. You should hear a hissing sound as air is released, followed by a reading on the gauge.

Compare this reading to the recommended tire pressure listed in your owner’s manual or on the tire information placard located on the driver’s side door jamb. If your tire pressure is too low or too high, add or release air as necessary until it matches the recommended pressure. By regularly checking your tire pressure with a tire pressure gauge, you can help prolong the life of your tires and ensure a safer and more efficient driving experience.

Refer to your vehicle’s manual for the appropriate tire pressure.

Checking the tire pressure of your vehicle is an essential step in ensuring safe and efficient driving. Step 1 in this process is to refer to your vehicle’s manual for the appropriate tire pressure. The recommended tire pressure can vary depending on the make and model of your vehicle, as well as the specific tires you have installed.

It’s crucial to follow the manufacturer’s guidelines to prevent underinflation or overinflation, both of which can cause issues with handling, braking, and fuel efficiency. Neglecting to check your tire pressure regularly can also lead to premature wear and tear, which can result in the need for costly repairs or replacements. Don’t underestimate the importance of this simple yet crucial step in maintaining your vehicle.

Take the time to refer to your manual and check your tire pressure frequently to ensure a safer, smoother ride.

Step 2: Locate the Valve Stem

Once you’ve determined that your tire valve stem needs tightening, it’s time to locate the valve stem. The easiest way to do this is to look for the small black or silver cap on the wheel itself. Even if you’ve never tightened your valve stem before, you’ve probably seen these caps before.

They protect the valve stem from debris and help keep air from escaping the tire. Simply unscrew the cap and you should see the valve stem protruding slightly from the wheel. If you’re having trouble finding the valve stem, you can try feeling around with your fingers or shining a flashlight directly at the wheel to help you locate it.

Once you’ve found the valve stem, you’re ready to move on to the next step in the process of tightening it.

The valve stem is the small, usually black, stem that protrudes from the tire.

The valve stem is an essential part of your tire that helps regulate the tire’s air pressure to keep your car running smoothly. It’s crucial to locate the valve stem for several reasons, the main one being filling your tires with air. Typically, the valve stem is a small, black, cylindrical protrusion that juts out from the tire.

In most cases, it’s easy to spot since it’s situated near the edge of the wheel. If you’re driving, it’ll be on the side that faces outwards, so you’ll have to stop the car and ensure that part is facing you. Once you find the valve stem, you need to inspect the cap on top since it keeps dirt and debris from getting inside and sticking to the valve.

The cap is small but noticeable, reliable in securing the valve to prevent air from leaking. Without the valve stem and its cap, your tire would be prone to damage quickly, causing more harm than good to your car. So, it’s good to be aware of the location and condition of your valve stem!

It is located on the rim, near the edge of the tire.

When it comes to checking your tire pressure, the valve stem is an essential part of the process. The valve stem is located on the rim, near the edge of the tire. It’s a small, cylindrical component that protrudes from the wheel and allows air to be pumped in or released from the tire.

To locate the valve stem, you’ll need to examine the outer edge of your tire. Look for a small rubber protrusion that sticks out from the rim. This will be the valve stem.

Why is the valve stem so important? Well, without it, you wouldn’t be able to inflate or deflate your tire. And as we all know, having properly inflated tires is crucial for maintaining control of your vehicle and ensuring a safe ride. So, the next time you need to check your tire pressure, don’t forget to locate the valve stem first.

Once you’ve found it, you can move on to the next step in the process.

Step 3: Use the Valve Stem Tool

When it comes to tightening your tire valve stem, using a valve stem tool is crucial. This handy tool is specially designed to fit over the valve stem and provide leverage for tightening it securely. Simply place the tool in position and use a firm grip to turn it clockwise until the valve stem is snug.

Be careful not to over-tighten as this could damage the valve stem or cause air leaks. When using the valve stem tool, you’ll want to make sure it’s the correct size for your valve stem, so it fits securely and doesn’t slip. By taking the time to properly use this tool, you can ensure that your tire stays properly inflated and safe for driving.

Insert the valve stem tool onto the valve stem and turn it clockwise.

Valve Stem ToolOkay, so you’ve successfully removed the old valve stem from your tire, and now it’s time to replace it with a new one. That’s where the valve stem tool comes in handy. This nifty little gadget slips onto the valve stem and is used to screw it into the valve hole on the rim.

The tool is designed to grip the narrow stem tightly while making it easy to turn it clockwise. This process ensures a tight fit, which means your tire pressure will be properly maintained.If you don’t have a valve stem tool, it’s an inexpensive investment that can save you time and money in the long run.

Trying to screw in the valve stem without a tool can be tricky, and you might end up damaging the stem or even the rim. Plus, the tool makes it so much easier to get the job done quickly and efficiently.Using the valve stem tool is straightforward once you get the hang of it.

Simply slide it onto the stem and then turn it clockwise until it’s firmly in place. Be careful not to over-tighten the stem, as this can also cause damage. A good rule of thumb is to tighten it until it’s snug, but not so tight that you can’t loosen it with a tool later if needed.

Overall, using the valve stem tool is an essential step when replacing a tire valve stem. It’s easy to use and can save you time, money, and frustration. Don’t forget to add one to your tool kit before you tackle your next tire repair job!

Tighten the valve stem until it is snug.

In step 3 of the valve adjustment process, you’ll need to use a valve stem tool to make the necessary adjustments. This tool helps you work more efficiently and accurately, ensuring that your valves are performing optimally. Begin by inserting the tool onto the valve stem, making sure that it fits snugly.

Next, use the valve stem tool to rotate the valve in a clockwise direction. As you do this, pay close attention to the feel of the valve and listen for any unusual sounds. You want to ensure that the valve is moving smoothly and that there are no signs of wear or damage.

Once you’re satisfied that the valve is moving freely, tighten the valve stem until it is snug. This will help ensure that your valves stay properly adjusted for maximum performance. By using the valve stem tool correctly, you’ll be able to complete the valve adjustment process quickly and reliably, ensuring that your engine runs smoothly for years to come.

Step 4: Check Tightness

After successfully threading the valve cap back on, it’s essential to double-check the tightness of your tire valve stem to prevent any further complications. You can use a valve cap tool or your fingers to tighten it. It’s crucial to ensure the valve cap is tightened enough to prevent any air leaks, but not too tight that it’s challenging to remove.

Over-tightening the valve cap can cause the rubber gasket to distort and fail, causing air to escape from the tire. Regularly checking the valve stem’s tightness can help ensure optimal tire pressure and avoid low tire pressure issues. So, always keep an eye on your tire valve stems and tighten them up whenever necessary to maintain the right pressure in your vehicles.

Check the tightness of the valve stem by gently pulling on it.

One of the most important steps in ensuring your tire’s longevity is checking the tightness of the valve stem. The valve stem is the tiny protrusion that allows air into the tire. Over time, it can become loose, which can cause the tire to lose air rapidly.

To check the tightness of the valve stem, gently pull on it. If it feels loose or wobbly, then it needs to be tightened. To do this, use a valve stem tool to take off the valve cap and then use pliers to tighten the valve stem.

Be careful not to over-tighten it as this can cause damage to the stem and the tire. It’s important to check the tightness of the valve stem regularly, especially before any long trips. Neglecting this simple step can lead to dangerous blowouts on the road.

So, take a few moments to give your valve stem a gentle tug and make sure it’s tightly secured before hitting the road.

If it moves at all, use pliers or an adjustable wrench to tighten it further.

When tightening any loose fittings or connections on your equipment, it’s essential to check their tightness afterward. Even if it feels secure, there’s always a chance that it could loosen up again and cause problems. Using pliers or an adjustable wrench, give the area a gentle tug to see if there’s any give.

If the part moves at all, it needs further tightening. However, be careful not to over-tighten it, which could cause damage or breakage. Think of it as tightening a jar lid – you want it snug enough to keep everything in place, but not so tight that you can’t easily unscrew it in the future.

With these simple steps, you can ensure that your equipment remains safe and in good working order, giving you peace of mind and a well-maintained setup.

Step 5: Check Tire Pressure Again

Before hitting the road, make sure to check your tire pressure once again after tightening the valve stem. Even a slight change in temperature can cause a drop in tire pressure, and driving on under-inflated tires can be dangerous. Use a tire pressure gauge to check the pressure in each tire and ensure that it matches the manufacturer’s recommended pressure levels.

If any tire requires additional air, use a tire inflator to fill it up to the proper pressure. Don’t forget to check the spare tire, too! By keeping the tire pressure at the recommended levels, you can improve fuel efficiency, extend your tires’ lifespan, and enhance your safety on the road. So take some time to check your tire pressure regularly and avoid any mishaps on your next journey.

And remember, tightening the tire valve stem is just one simple step in ensuring your tires are properly maintained.

Check the tire pressure again to ensure it is still at the appropriate level.

After ensuring that all four of your tires are inflated to the appropriate levels, it is essential to check the tire pressure again. This step is just as important as the initial pressure check that you did before. Why? Well, the answer is quite simple – tire pressure can change over time due to various factors such as temperature changes and natural air leakage.

Thus, checking the tire pressure again will ensure that your car is at maximum fuel efficiency and that your tires are in their best condition. To check the tire pressure, use a reliable tire pressure gauge and measure each tire’s pressure again. The optimal pressure level will be found in your car’s manual or on a sticker located on the driver’s side door.

If the pressure is still good to go, congratulations! You’re good to hit the road. If not, then re-inflate the tire until it reaches the optimal pressure level. In conclusion, checking the tire pressure twice will ensure that your tires are in their best condition and your car runs efficiently, ultimately saving you from unforeseen car troubles.

Conclusion

In conclusion, tightening a tire valve stem may seem daunting, but it’s as easy as twisting a bottle cap. And just like a twist-off cap on a cold brew, a well-tightened tire valve stem ensures a smooth and refreshing journey. So grab a wrench, channel your inner barkeep, and give those valve stems a good twist.

Your tires will thank you for it.”

Tightening your tire valve stem is an easy process that can improve the safety and performance of your vehicle.

After tightening the valve stem on your tire, it’s important to recheck the tire pressure to ensure that it’s at the desired level. A tire that’s overinflated can lead to a rough ride and decreased handling, while an underinflated tire can cause poor fuel efficiency and increase the risk of a blowout. To check the tire pressure, use a tire pressure gauge to measure the pressure in each tire, and compare the readings to the recommended pressure listed in your vehicle’s owner manual or on the tire itself.

If the tire pressure is too high or too low, adjust it accordingly and recheck the pressure until it’s within the recommended range. Keeping your tires properly inflated not only improves the performance of your vehicle but also increases safety on the road. So, make sure to add checking the tire pressure to your routine maintenance checklist, and enjoy a safer and smoother ride.

FAQs

What is a tire valve stem?

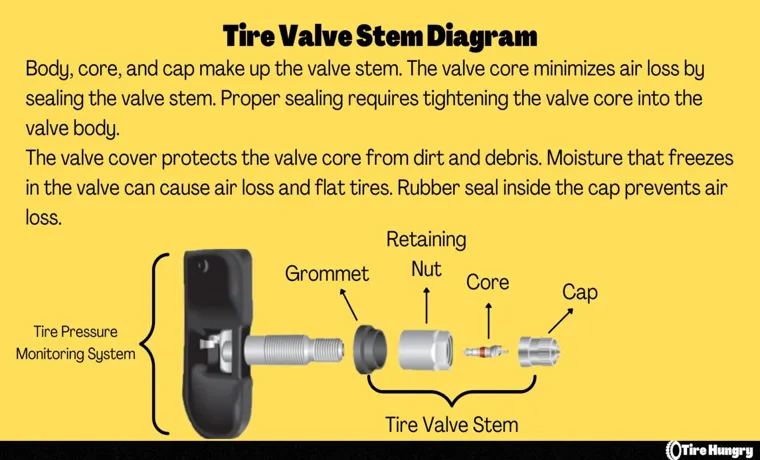

A tire valve stem is the part of the tire that makes the connection between the tire and the inflation device. It allows you to inflate or deflate your tires.

How do I know if my tire valve stem is loose?

You can check the tightness of your tire valve stem by gently trying to turn it. If it moves easily, it’s likely loose.

What tool do I need to tighten my tire valve stem?

You can tighten your tire valve stem using a valve stem wrench, which can be purchased at most auto parts stores.

How tight should I make my tire valve stem?

You should tighten your tire valve stem until it is snug, but be careful not to over-tighten it, as this can cause damage to the valve stem or the tire itself.

What do I do if my tire valve stem is damaged?

If your tire valve stem is damaged, it should be replaced as soon as possible. You can take your car to a mechanic to have the valve stem replaced, or purchase a replacement valve stem and do it yourself if you’re comfortable with that.

Can a loose tire valve stem cause a flat tire?

Yes, a loose tire valve stem can cause a slow leak or even a flat tire, as it can allow air to escape from the tire.

How often should I check the tightness of my tire valve stems?

It’s a good idea to check the tightness of your tire valve stems every time you check your tire pressure, which should be done at least once a month.