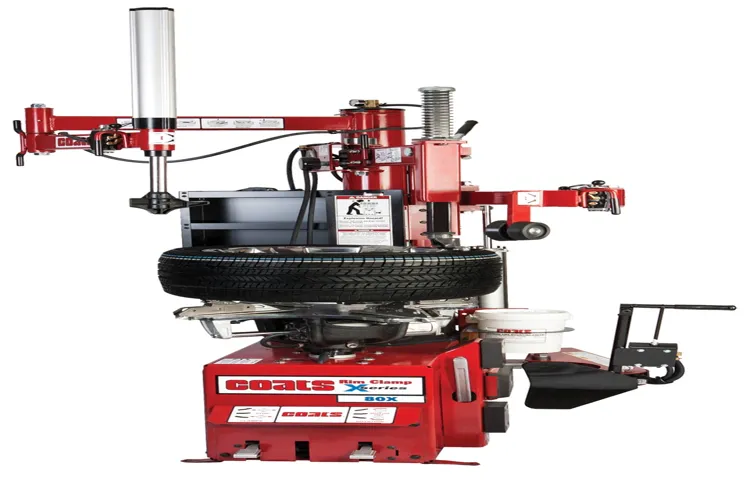

Tire mounting and balancing can be a daunting task, especially for novice mechanics. A tire changing machine drastically reduces the time and effort it takes to perform this task. One of the most reliable tire machines available in the market is the Coats tire machine.

But do you know how to use it? Using the right tire machine can make all the difference in ensuring that your tire is mounted safely and securely, making your job easier, faster, and more efficient. In this blog post, we’ll go through everything you need to know on how to use a Coats tire machine, step by step. So, whether you’re a professional or just a DIY enthusiast, read on to discover how to get the most out of your tire machine and get your vehicle road-ready in no time!

Table of Contents

Preparing the Machine

If you’re new to the world of tire-changing, using a Coats tire machine can seem like a daunting task. But fear not – with a bit of preparation, you’ll be able to master the machine in no time. First and foremost, be sure to read the machine’s user manual thoroughly before even touching it.

Once you’re familiar with the machine’s ins and outs, be sure to prep your workspace. This means ensuring you have all the necessary tools and supplies, including proper work gloves, lubricant, and spare tire valves. Pick a well-lit and ventilated area, and make sure you have ample space to work in.

Finally, before starting the machine, inspect it to make sure everything is in good working order. Check for loose connections, frayed cords, and any other signs of wear and tear. By taking the time to prepare your workspace and equipment, you’ll ensure a smoother and safer tire-changing process.

Check the Air Pressure

When it comes to using your machine, it’s important to ensure that it’s in tip-top condition. Before you set off, it’s essential to check the air pressure of your tires. Proper air pressure is crucial to the performance and safety of your vehicle.

You can find the recommended air pressure for your machine in the owner’s manual or on the tire itself. Using a tire pressure gauge, check each tire and inflate or deflate as necessary. Riding on underinflated tires can cause excessive heat buildup, causing a blowout, while overinflated tires can cause uneven wear and reduce traction.

Checking your tire pressure is a quick and easy task that you should make a habit of before each ride. It will ensure that your ride is safe and comfortable every time you hit the road.

Inspect the Tire Changer

When it comes to using a tire changer, the first step is to inspect the machine and make sure it’s ready to use. Before starting, you’ll need to ensure that the machine is in good working condition, and that all of the necessary parts are in place. Begin by checking the hydraulic fluid level, and top it off if necessary.

Next, inspect the chuck, bead breaker, and other components to make sure they’re properly installed and functioning correctly. Finally, double-check that all of the bolts, nuts, and screws are tightened, and that the machine is properly grounded. Taking the time to inspect the tire changer before using it can help prevent accidents and ensure that you get the job done safely and efficiently.

Removing the Tire

Learning how to use a Coats tire machine involves several essential steps, starting with removing the tire from the vehicle. First, use a lug wrench to loosen the lug nuts, but don’t remove them entirely yet. Then, use either a car jack or lift to raise the vehicle off the ground.

Once the car is elevated, remove the lug nuts and carefully lift the tire off the car. It’s important to remember to support the tire’s weight with your hands, as it can be heavy and cause injury if dropped. Once the tire is completely removed from the car, you can move forward with using the Coats tire machine to change the tire or repair it.

Knowing how to safely remove a tire is crucial before attempting to use a tire machine effectively.

Loosen the Lug Nuts

Loosening the lug nuts is a crucial step when it comes to removing a tire. To do this, you will need a lug wrench and some elbow grease. First, find the lug nuts on your tire and place the wrench over them.

Make sure the wrench fits snugly over the nuts before applying pressure. Then, using your body weight, turn the wrench counterclockwise to loosen the nuts. You may need to use some force, especially if they have been tightened too tightly in the past.

It’s important to loosen all the nuts before lifting the vehicle with a jack. Remember to never remove the lug nuts completely until the tire is off the ground to avoid any accidents. Once all the nuts are loose, you can proceed to remove the tire and complete any necessary repairs.

Taking the time to properly loosen the lug nuts will make removing the tire a safer and smoother process.

Place the Tire on the Machine

Removing the tire is a crucial step before placing it on the machine. To remove the tire, loosen the lug nuts with a wrench and place the jack under the car. Lift the car off the ground and remove the lug nuts completely.

You can now take the tire off, pulling it straight out towards your body. Be cautious as the tire can be heavy and bulky, requiring extra effort to remove. Once you have removed the tire, it’s time to place it on the machine.

The best way is to align the tire with the machine’s center and use the machine’s jaws or clamps to secure it in place. Make sure the tire is tightly secured before proceeding to the next step. This will ensure the tire doesn’t move during the process, allowing you to work on it without any disruptions.

Remember, always wear protective gear while working with tires as it can be dangerous.

Adjust the Tool Arm

Adjusting the tool arm is an essential skill that every car owner should know. One of the most common tasks that require adjusting the tool arm is removing a tire. When you want to remove a tire, the first step is to loosen the lug nuts.

Once you have done that, you can use the jack to lift the car and remove the tire. However, if the tire is stuck, you may need to adjust the tool arm. To do this, you will need to use the handle to loosen the nuts on the tool arm.

This will allow you to move the arm into a better position to remove the tire. After you have adjusted the tool arm, use it to remove the tire. With some practice, adjusting the tool arm will be a breeze, and you will be able to change tires like a pro.

Push the Bead Breaker

If you’re planning to remove a tire, the first thing you’ll need to do is push the bead breaker. This is a tool that’s designed to loosen the tire from the rim, making it much easier to take off. Pushing the bead breaker involves inserting it into the tire and then using a lever to apply pressure to the sidewall.

This will shift the tire enough to break the seal between the tire and rim. Once the bead breaker is securely in place, push down on the lever to release the tire. Make sure you apply enough force to loosen the tire but not so much that you cause damage to the rim.

With a little practice, you’ll soon master the art of pushing the bead breaker and be able to remove tires with ease. Remember to wear appropriate safety gear while working on your vehicle and never work on tires that are still inflated.

Disengage the Bead

Disengaging the bead during tire removal can seem like a daunting task, but with the right tools and techniques, it can be done easily and safely. Starting with loosening the lug nuts, jack up the vehicle and securely place it on jack stands. Using a tire iron or wrench, remove the lug nuts and take off the wheel.

Next, locate the valve stem and remove the valve core to release the air pressure in the tire. With a bead breaker tool, apply pressure to the sidewall of the tire to break its seal with the rim. Now, use tire levers to pry the bead over the rim and remove the tire from the rim.

Be mindful of the tire beads, as they can be tightly squeezed, making the process more difficult. When complete, inspect the tire and rim for any damage and proceed with tire replacement or repairs. Remember, proper safety precautions and procedures should always be followed when working with tires.

Remove the Tire

First things first, before you can make any repairs to your tire, you’ll need to remove it from your vehicle. This may seem like a daunting task, but with the right tools and a little bit of patience, it’s definitely doable. Start by loosening the lug nuts on the tire with a lug wrench.

Be sure to only loosen them and not take them off completely just yet. Next, raise your vehicle with a jack until the tire is completely off the ground. Now you can safely remove the lug nuts and take the tire off.

It’s important to remember to always use caution when working with jacks as they can be dangerous if not used correctly. Once the tire is removed, you can inspect it for any damage or punctures, and if necessary, make the necessary repairs or replacement. By following these simple steps, you can remove your tire safely and efficiently, and get back on the road in no time.

Installing a New Tire

If you’re wondering how to use a Coats tire machine to install a new tire, the process can be broken down into several steps. First, you’ll need to remove the old tire from the wheel using the machine’s demount head. After that, it’s time to mount the new tire onto the wheel using the mount head.

The key is to make sure the tire is properly centered and that the bead is seated evenly. Once the tire is mounted, inflate it to the appropriate pressure and balance the wheel using the machine’s balancing arm. It’s important to remember to use the proper safety equipment, such as gloves and eye protection, throughout the process.

With a bit of practice and patience, using a Coats tire machine can become second nature and make the task of installing new tires quick and easy.

Mount the Tire on the Machine

When it comes to installing a new tire, the last step is mounting it onto your machine. This step requires a bit of finesse and attention to detail, but it’s not too difficult if you follow the proper procedure. First, make sure that the rim is clean and free of any dirt or debris that could interfere with the seal between the tire and rim.

Then, carefully line up the tire with the rim, making sure that the valve stem is centered and that the tire is sitting evenly on the rim. Using a tire iron, work your way around the tire, gradually pushing the bead onto the rim. Be patient and take your time, making sure not to pinch the inner tube or damage the tire in any way.

Once the tire is fully seated on the rim, inflate it to the recommended pressure and check for any leaks or bulges. And there you have it – a brand new tire installed and ready to go!

Lubricate the Tire and Rim

When installing a new tire, it is crucial to lubricate the tire and rim to ensure a smooth and easy installation process. Without proper lubrication, it can be difficult to fit the tire onto the rim, and it can even cause damage to both the tire and rim. One of the best lubricants to use is soapy water, as it provides just the right amount of slipperiness without being too greasy.

To apply it, simply pour some soapy water onto the rim and tire, making sure to spread it evenly. Then, use your hands to gently massage the tire onto the rim, being careful not to force it or use too much pressure. If the tire is still hard to install, you can add more lubrication as needed.

By taking the time to properly lubricate your tire and rim, you can save yourself a lot of frustration and potential damage, and ensure that your new tire is installed correctly and safely.

Align the Tire on the Rim

Installing a new tire can be intimidating, but with the right tools and knowledge, it’s a task anyone can tackle. One crucial step in the installation process is aligning the tire on the rim. Ensuring proper alignment not only improves the tire’s lifespan but also enhances your driving experience.

To start, place the tire on the rim and align the valve stem with the hole in the rim. Next, gently push the tire down onto the rim, making sure it sits evenly around the circumference. Use a mounting lubricant if needed to ease the process.

As you continue to push the tire onto the rim, check its alignment periodically. Once the tire is fully mounted, double-check that it’s sitting evenly and the valve stem is straight. Proper alignment will provide optimal performance and safety on the road.

Inflate the Tire

After successfully installing a new tire, the next step is to inflate it to the recommended pressure levels. Under-inflated tires can negatively impact the performance of your vehicle and even cause safety concerns on the road. The process of inflating a tire is fairly simple, but it’s important to take certain precautions.

First and foremost, make sure to use the correct tire pressure gauge and check the recommended pressure levels for your specific vehicle. Then attach the gauge to the valve stem and check the pressure, gradually adding air until you reach the recommended level. It’s important not to overinflate the tire, as this can lead to blowouts or uneven tire wear.

Regularly checking and maintaining the proper tire pressure can improve fuel efficiency, handling, and overall safety on the road. So don’t neglect this important step after installing a new tire!

Balance the Tire

When installing a new tire, one crucial step is to balance it. Balancing ensures that the tire rotates evenly and prevents vibrations while driving. The process involves placing small weights on the wheel to counterbalance any heavy spots.

Although unbalanced tires may seem like a small issue, they can cause bigger problems down the line, such as uneven wear on the tire and suspension components. So it’s essential to balance the tire to maintain the vehicle’s stability and performance on the road. Don’t overlook this crucial step when installing a new tire.

It’s worth the short amount of time and extra cost to ensure a smooth and safe ride.

Tips and Tricks

If you’re a new auto mechanic or simply a do-it-yourself enthusiast, it’s important to know how to use a Coats tire machine properly. It’s an essential tool when it comes to changing tires and can save you a lot of time and effort. The first step is to ensure that you have the right machine for the job.

Select the machine based on the type of tires you’ll be working on, as different machines are designed for different types. Once you have your machine, be sure to familiarize yourself with its functions and features by reading the user manual. Next, make sure to properly balance the tire and wheel before using the machine.

This step is important as it will prevent any vibrations while driving. Additionally, always double-check the air pressure to ensure proper inflation. Lastly, make sure to use the appropriate safety gear such as gloves and eye protection to prevent any accidents that may occur during the process.

With these tips and tricks, you’ll be able to use your Coats tire machine with confidence and efficiency.

Practice Safety Measures

Practicing safety measures is crucial to maintain a healthy and secure lifestyle. Here are some tips and tricks to ensure your safety while at home or outdoors. Firstly, always wear a face mask and maintain social distancing protocols to prevent the spread of COVID-1

Additionally, installing smoke detectors and carbon monoxide detectors throughout your home can alert you of any potential hazards. Furthermore, ensure that your home’s windows and doors are securely locked before leaving or sleeping, stay in well-lit areas at night, and don’t walk alone if possible. Another important safety measure is to keep an emergency kit and first aid supplies at hand in case of an emergency.

Remember, implementing these simple tricks can save your life and prevent harm to you and your loved ones. So, stay safe and take every precaution necessary to ensure your protection from any potential harm.

Read the Manual

When it comes to using new technology or devices, many of us are tempted to ignore the instructions and dive right in. However, reading the manual can save you a lot of time, effort, and frustration in the long run. The manual is designed to provide clear and concise information, helping you understand how things work and how to use them efficiently.

Even if you’re confident in your abilities, taking the time to read the manual can also help you uncover hidden or advanced features that you may not have discovered otherwise. So, the next time you unbox a new gadget, take a deep breath, set aside some time, and read the manual. You might be surprised at how much easier and enjoyable it makes the experience.

Remember, a little bit of effort upfront can save you a lot of hassle in the end and improve your overall experience.

Get Trained

If you’re looking to improve your skills and knowledge, getting trained is a great way to do so. There are many tips and tricks to make the most out of your training experience. First and foremost, it’s important to set clear goals for yourself and understand what you want to achieve from the training.

This will help you stay motivated and focused throughout the process. Additionally, it’s important to actively engage during the training by asking questions, participating in discussions, and taking notes. This not only helps you retain more information, but it also shows your trainer that you’re invested in the process.

Finally, once the training is complete, it’s essential to put what you’ve learned into practice. This solidifies the knowledge and ensures that it becomes a valuable asset to you. Overall, getting trained can be a powerful tool to help you grow both personally and professionally.

So, don’t hesitate to invest in yourself and start learning today!

Inspect the Machine Regularly

Inspecting your machine regularly is a key aspect of keeping it running smoothly and ensuring longevity. By regularly checking your equipment, you can spot problems early before they escalate and cause more damage. It also allows you to identify areas that need extra attention and perform adequate maintenance to prevent costly repairs.

Some tips and tricks for inspecting your machine include checking all moving parts, examining the electrical connection, and inspecting all fluids, such as oil and coolant. You should also keep a record of any maintenance or repairs you perform, including the date, so you can track the machine’s performance over time. The keyword “machine inspection” is vital for improving the health of your equipment and maximizing its lifespan for optimal performance.

By adopting these best practices, you can stay ahead of potential issues and ensure your machine is kept in excellent condition.

Conclusion

So there you have it, folks – the ultimate guide on how to use a Coats tire machine! With a bit of practice and patience, you’ll be changing tires like a pro in no time. Keep in mind that tire changing is both an art and a science – it requires just the right touch, a bit of finesse, and some serious know-how. But with the right mindset and a good understanding of the process, you’ll soon be performing tire changes like a boss.

And who knows, maybe you’ll even start your own tire-changing business. Just remember to use the right tools, pay attention to safety, and have fun – because at the end of the day, that’s what matters most!”

FAQs

What is a Coats tire machine?

A Coats tire machine is a type of equipment used to mount and demount tires from wheels.

How do I operate a Coats tire machine?

To operate a Coats tire machine, you first need to secure the wheel onto the machine using the appropriate clamps. Then, use the machine’s controls to mount or demount the tire as needed.

Is it safe to use a Coats tire machine?

Yes, it is generally safe to use a Coats tire machine as long as you follow the manufacturer’s instructions and safety guidelines. Make sure to wear appropriate safety gear and use caution when working with heavy machinery.

Can a Coats tire machine be used for all types of tires?

Coats tire machines are designed to work with a wide range of tire sizes and types, but it’s important to verify that the machine you have can handle the specific tires you are working with.

How do I maintain my Coats tire machine?

Regular maintenance is important to keep your Coats tire machine in good working condition. This may include tasks such as checking and replacing worn parts, lubricating moving components, and keeping the machine clean and free of debris.

What should I do if my Coats tire machine isn’t working correctly?

If you experience any issues with your Coats tire machine, it’s important to discontinue use immediately and troubleshoot the problem. This may involve consulting the machine’s owner manual or contacting a professional for assistance.

Can a Coats tire machine be used in a commercial auto shop?

Yes, Coats tire machines are commonly used in commercial auto shops and other professional settings. However, you may need to invest in a higher-end model if you are handling a high volume of work.